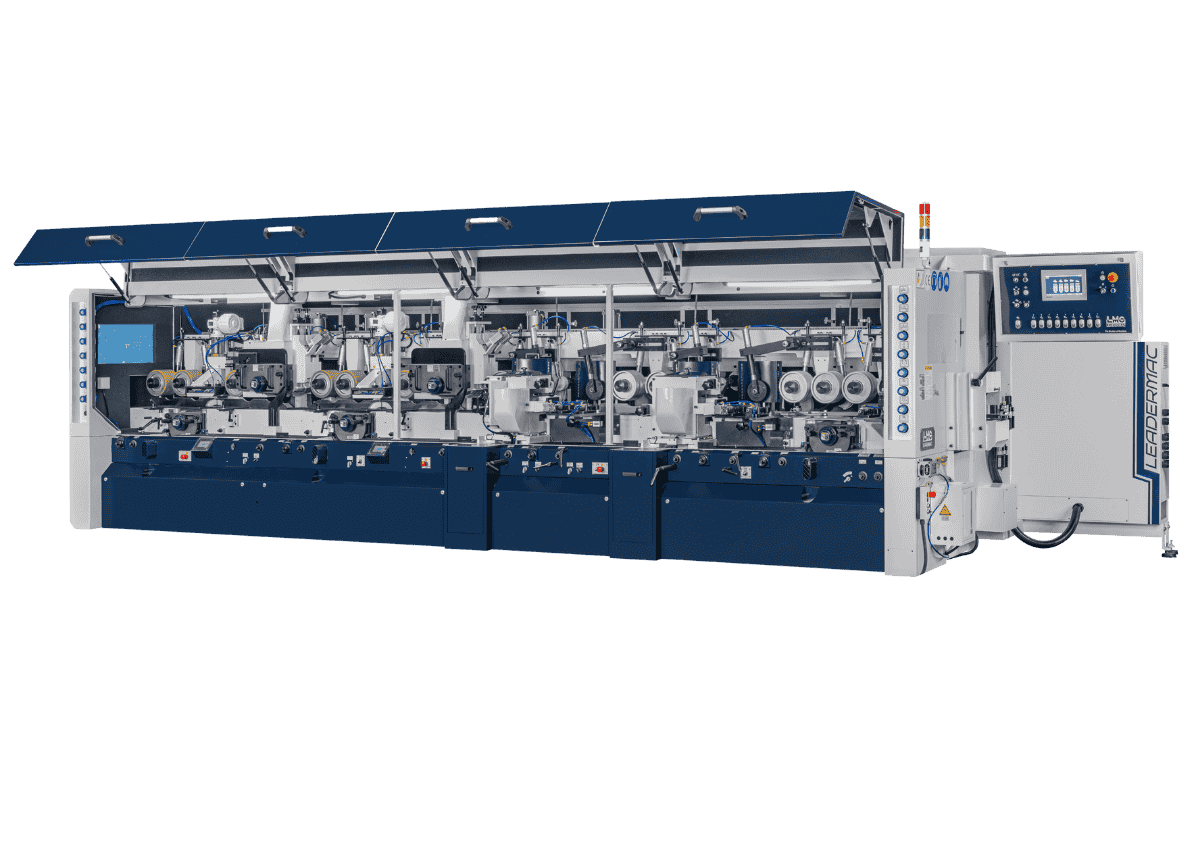

THUNDERMAC 80-200 m/min Jointed Moulder

The Modern Way to Achieve Productivity and Profitability

Delivering Unparalleled Speed and Power in a High-Efficiency Automated System

THUNDERMAC 80-200 m/min Jointed Moulder

The Modern Way to Achieve Productivity and Profitability

Delivering Unparalleled Speed and Power in a High-Efficiency Automated System

OUTSTANDING FEATURES

- All moulders with CE Certification if desired.

- Faster feed speeds of up to 80 meters a minute (265 FPM) are standard – to 200 mpm (656 FPM) – optional.

- Programmable Controller provides convenient thickness and width of cut settings.

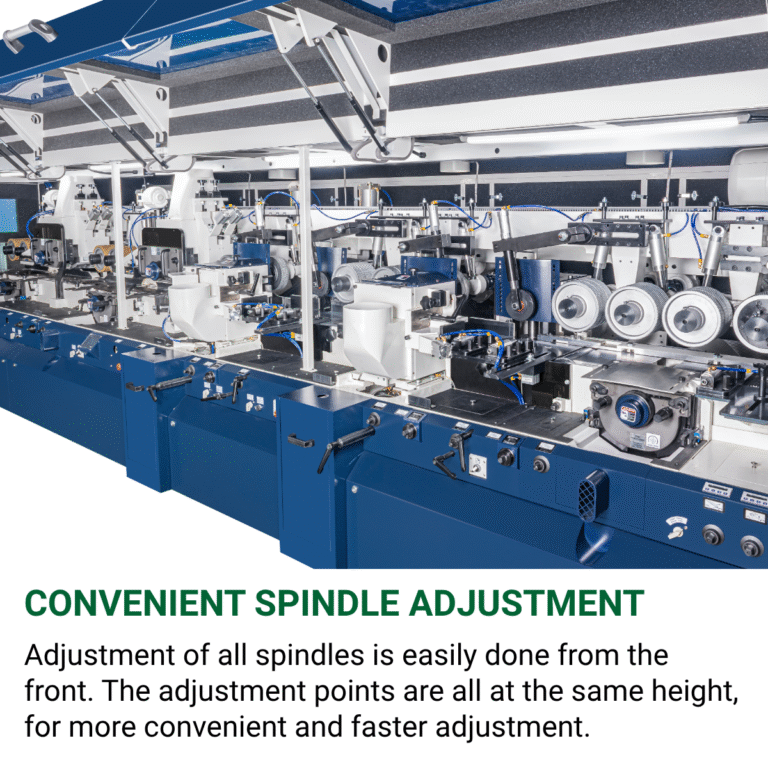

- Adjustment of each spindle can be easily performed using the front of the machine adjustment.

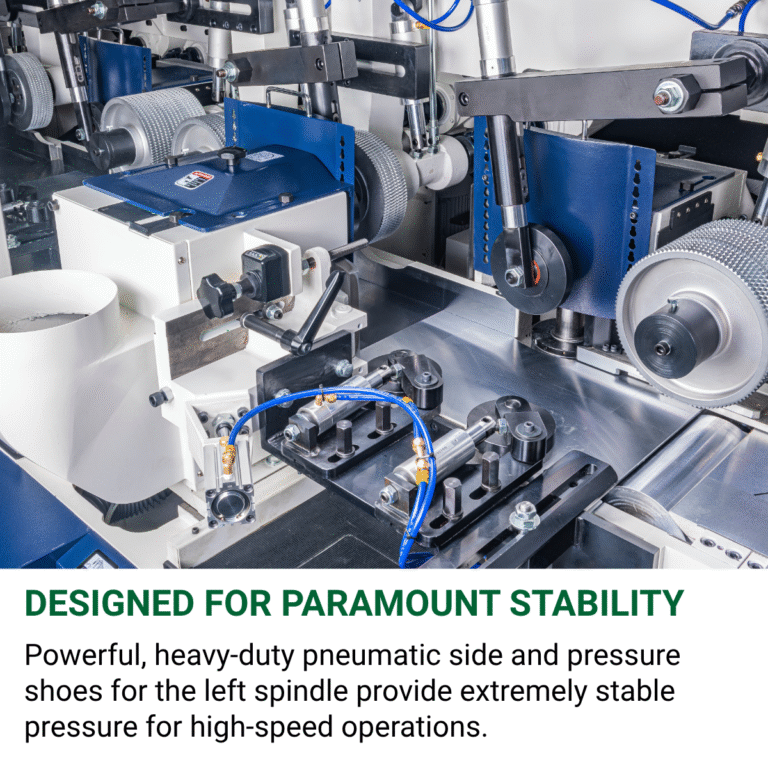

- Exclusive, separate adjustment of the vertical spindles and the support tables allows the tables to be positioned extremely close to the cutterheads for added cutting stability.

- The full safety enclosure serves as a chip guard and helps to reduce noise and is equipped with Strobe Free Lighting.

- Each spindle is driven by an individual motor for powerful moulding and easy control.

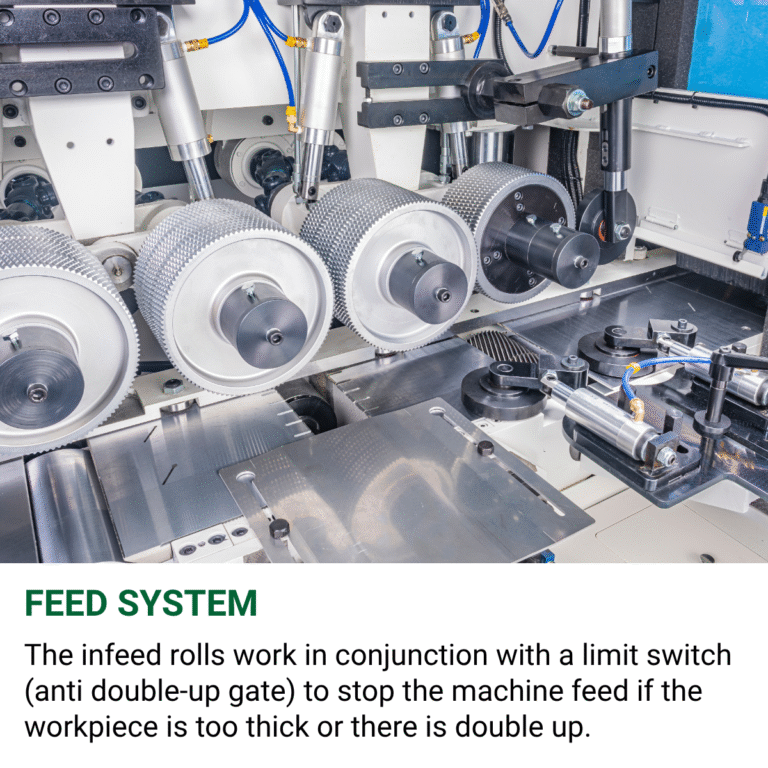

- Multiple pneumatic pressure of the feed rolls can be easily set to provide an outstanding feeding effect.

- Table surfaces, guides, chip Breaker shoes and Pressure plates are hard-chrome plated for maximum wear resistance.

- All manually adjusted & turning parts are housed in dry grease lubricated bearings for oil-free lubrication.

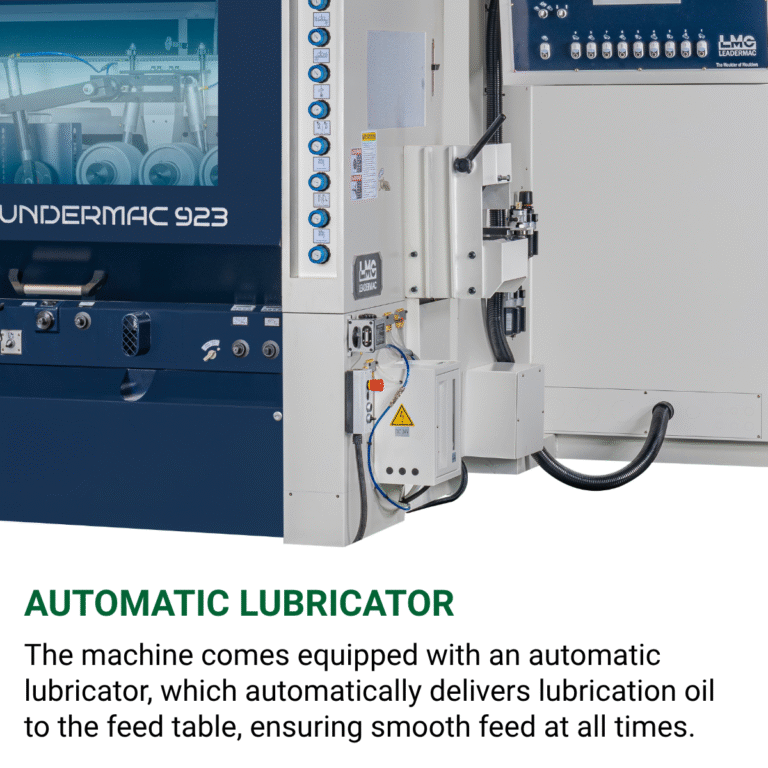

- Automatic lubricator is provided to supply oil to the feed tables.

- One-piece, Extra Heavy machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

- The powered Top & Bottom Full Width rolls provide stable and smooth workpiece outfeed even for especially thin or smooth materials.

- The rolls remain perfectly parallel even after long-term use.

- Mechanical digital Readouts for all head axis and pressure elements & Chip Breaker Shoes and Pressure Plates of the Top spindle(s).

- Sectional Chip Breaker Assembly in front of top spindle(s).

- Finest Alloy Steel Spindles and housings with 2 sets of Ultra Precision Duplex Bearings in each spindle.

- All are perma- nently grease lubricated.

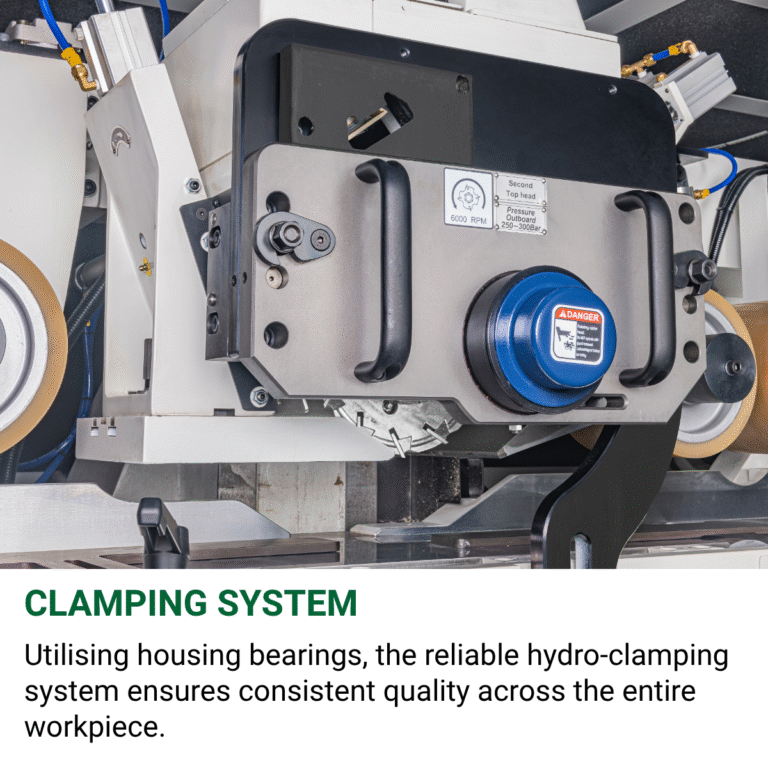

- All horizontal Spindles outfitted with Quick Lock Hydro-lock Outboard Bearings and Cutterhead supports.

- Built in Straight & Profile jointers provide accurate operation with high quality finish.

- The full Safety Enclosure is heavy gauge steel & serves as a chip guard and helps reduce noise. (optional)

FEATURES

TECHNICAL SPECIFICATIONS

| STANDARD EQUIPMENT | Available Options | |

| Number of Spindles (Min – Max) | 2 to 11 | |

| Working width (with a head cutting circle of 163mm) | 20~230mm (0.78″~9.1″) | 300mm (12″) |

| Working Thickness (with a head cutting circle of 163mm) | 10~150mm (0.39″~6″) | to 200mm (8″) |

| Basic Spindle Motor capacity (Wye Delta Soft Starts on All Motors) | 15 & 22 KW / 20 & 30HP | to 45KW (60HP) |

| Spindle Speed | 6000 RPM | 7200 RPM or 8000 RPM |

| Spindle Diameter | 50mm or 1 13/16″ or 2 1/8″ | |

| Tool Cutting Circle,1st Bottom Spindle, min-max | 160~260mm (6.3″~10.25″) | |

| Tool Cutting Circle, Vertical Spindles,min-max | 160~260mm (6.3″~10.25″) | |

| Tool Cutting Circle, Horizontal Spindles, Top, min-max | 160~260mm (6.3″~10.25″) | |

| Tool cutting circle, Horizontal Spindles, Bottom, min-max | 160~260mm (6.3″~10.25″) | |

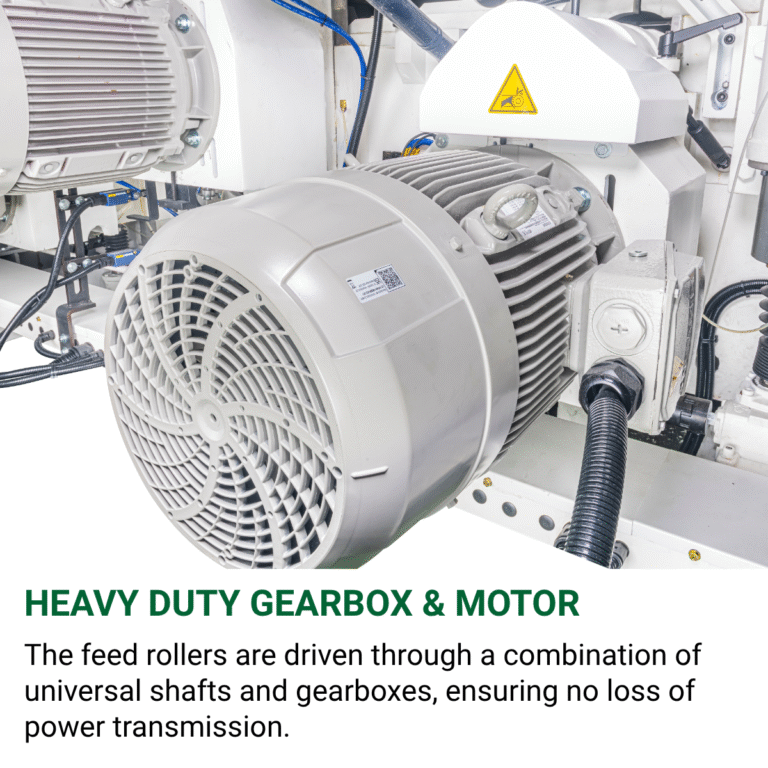

| Feed Motor – Standard | 15 KW / 20HP | to 30kw (40 HP) |

| Feed Speed, infinitely variable by VFD Inverter duty Motor | 8-80 m/min (25~265FPM) | 120m/min(400FPM), 160m/min(533FPM), 200m/min(656FPM) |

| Top Feed Roller Diameter | 205.36mm (8″) | |

| Top Feed Roller Width | 3 x 50mm (2″) | |

| Pneumatic Pressure for feed rollers, max | 6 bar (85psi) | |

| Adjustment range for Infeed Table and edge-jointing Fence | 10mm (0.4″) | |

| Adjustment range for Vertical Spindles (axial) | 80mm (3.2″) | |

| Adjustment range for Horizontal spindles (axial) | 40mm (1.6″) | |

| Length of the Infeed Straightening Table | 0.8M (32″) | |

| Clutch Roll on 1st top Infeed Roll | Included | |

| Digital Readout and Quick Set to Main guide & Infeed Rolls(Btm Head Cut-table) | Included | |

| Quick Set Setworks on Near Side Head(s) & Top Head(s) (Radial Set) | optional | |

| Mechanical Digital Readouts for the Spindles, Top Head Chip Breakers | Included | Extra Insulation with Steel Punched Sheet Steel Ineterior |

| Full Sound and Safety Enclosure w/ Strobe-free Lighting | Included | |

| Motorized vertical adjustment of Feed Beam with Top Feed Rolls | Included | |

| Pneumatic Lateral Pressure Roller Systems on Infeed & opposite first right spindle | Included | |

| Extra HD Chainless Cardan Shaft Feed System w/ExHD Gearboxes | Included | optional on all Axis and SmartSet Controls as noted Below optional |

| Diameter of Dust Hood for Vertical Spindles | Ø200mm (7.9″) | |

| Diameter of Dust Hood for Horizontal Spindles | Ø230mm (9.1″) | |

● All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT : | |

| Straight or Profile Jointers on any heads | Left (Opposite) Hand Feed |

| Remote Jointer Control | Cutterhead Lift Off Crane |

| Tilting Side Heads – to 45 degrees | Rip Saw Section with up to 56kw (75HP) |

| Split Top Head Pressure Shoes | Additional Quick Set Setworks on any desired Cutterhead Axis |

| Directly Opposed Side Heads | |

BESPOKE FACTORY OPTIONS

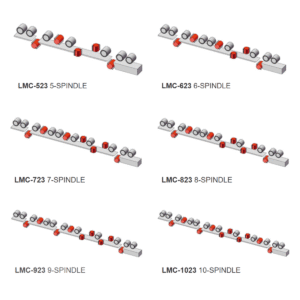

A Wide Range of Spindle Configurations

(other configurations available on request)

CONTROLLERS