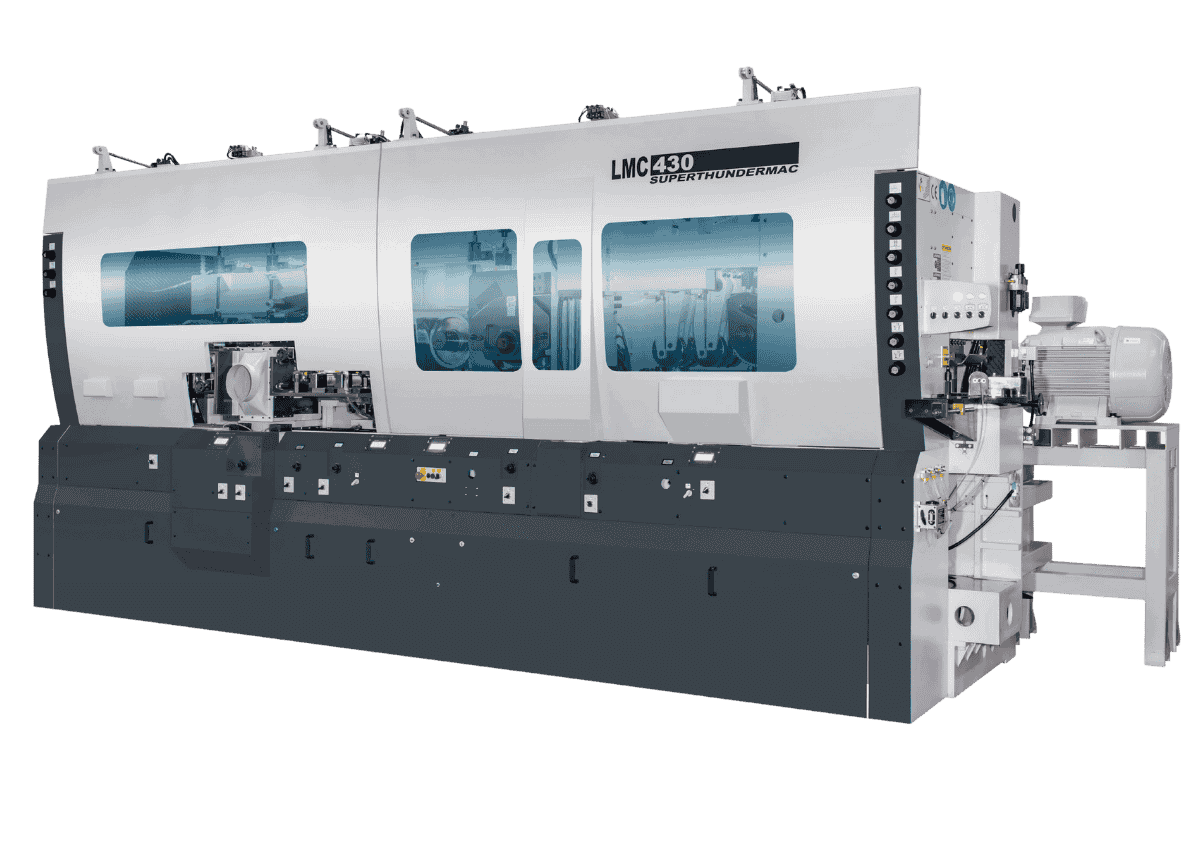

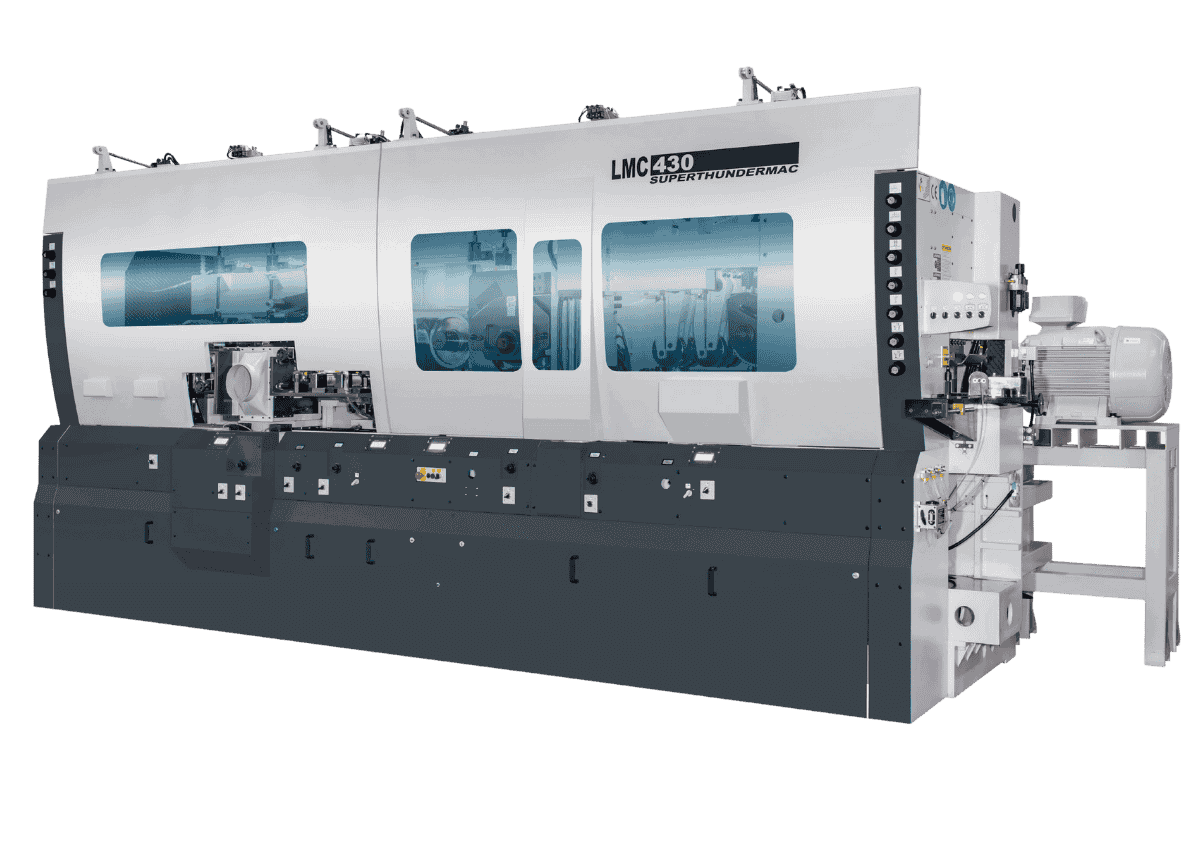

SUPER THUNDERMAC 200-400 m/min Jointed Moulder

Latest Advances in High Speed Moulding!

SUPER THUNDERMAC 200-400 m/min Jointed Moulder

Latest Advances in High Speed Moulding!

OUTSTANDING FEATURES

- All moulders awarded with CE certification.

- Faster feed speeds of up to 200 meters a minute (656 fpm) are standard – to 400 mpm – optional.

- Adjustment of each spindle can be easily performed using the front adjustment level.

- Exclusive, separate adjustment of the vertical spindles and the support tables allows the tables to be positioned extremely close to the cutterheads for added cutting stability.

- Each spindle is driven by an individual motor for powerful moulding and easy control.

- Multiple pneumatic pressure of the feed rolls can be easily set to provide an outstanding feeding effect.

- Table surfaces are hard-chrome plated for maximum wear resistance.

- All manually adjusted and turning parts are housed in dry grease lubricated bearings for oil-free lubrication.

- Automatic lubricator is provided to supply oil to the feed tables.

- Extra Heavy machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

- The powered outfeed rollers provide stable and smooth workpiece outfeed even for especially thin or smooth materials. The rollers remain perfectly parallel even after long-term use.

- Mechanical digital readouts for the pressure elements of top spindle.

- Sectional Chip Breaker Assembly in front of top spindle.

- Finest Alloy Steel Spindles and housings with 2 sets of Ultra Precision Duplex Bearings in each spindle. All are permanently grease lubricated.

- Built in Straight and Profile jointers provide accurate operation with high quality finish (Opt.)

FEATURES

TECHNICAL SPECIFICATIONS

| STANDARD EQUIPMENT: | Standard Base Equipment | Available Options |

| Working width | 30-400mm(1.18″-11.8″) | |

| Working Thickness | 10-150mm(0.4″-5.9″) | |

| Number of spindles, min-max | 4 to 10 | |

| Motor capacity per spindle | 37kw / 50HP | 45 kw / 60 HP |

| Spindle speed | 6,000 RPM | |

| Spindle diameter 60mm – std. | 60mm (2 3/8″) | |

| Head cutting circle, 1st bottom spindle, min-max | 160-260 mm (6.3″-10.24″) | 200-300 mm (7.87″-11.8″) |

| Head cutting circle, vertical spindles, left, min-max | 160-260 mm (6.3″-10.24″) | 200-300 mm (7.87″-11.8″) |

| Head cutting circle, vertical spindles, right, min-max | 160-260 mm (6.3″-10.24″) | 200-300 mm (7.87″-11.8″) |

| Head cutting circle, horizontal spindles, top, min-max | 160-260 mm (6.3″-10.24″) | 200-300 mm (7.87″-11.8″) |

| Head cutting circle, horizontal spindles, 2nd/3rd bottom, min-max | 160-260 mm (6.3″-10.24″) | 200-300 mm (7.87″-11.8″) |

| Standard Feed motor | 56 kw / 75 HP | 75 kw / 100 HP |

| Feed speed, infinitely variable by frequency driven motor | 30-200 m/min (98-656 fpm) | 30-300 m/min |

| Feed roller diameter | 300 mm (11.8″) | |

| Feed roller width | 4 x 50 mm (2 x 1.97″) | |

| Pneumatic pressure for feed rollers, max | 6 bar | |

| Adjustment range for infeed table and edge-jointing fence | 10mm (0.4″) | |

| Adjustment range of vertical spindles (axial) | 100 mm (3.94″) | |

| Adjustment range of horizontal spindles (axial) | 40mm (1.58″) | |

| Length of the straightening (moulder infeed) table | 1.57 M | |

| Diameter of dust hood for vertical spindle | Ø200 mm (7.87″) | |

| Diameter of dust hood for horizontal spindle (top / bottom) | Ø250 mm (9.84″) / Ø200 mm (7.87″) |

* All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT: | |

| Fence & table with cooling system | Straight jointer(s) |

| Maximum working thickness 180 mm (7.1″) | Profile jointer(s) |

| Increased motor horsepower available |

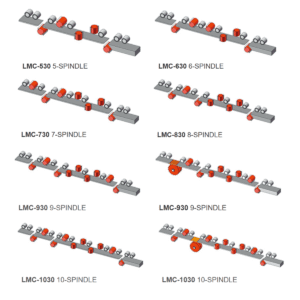

BESPOKE FACTORY OPTIONS

Wide Range of Spindle Configurations

(other configurations available on request)

Controllers