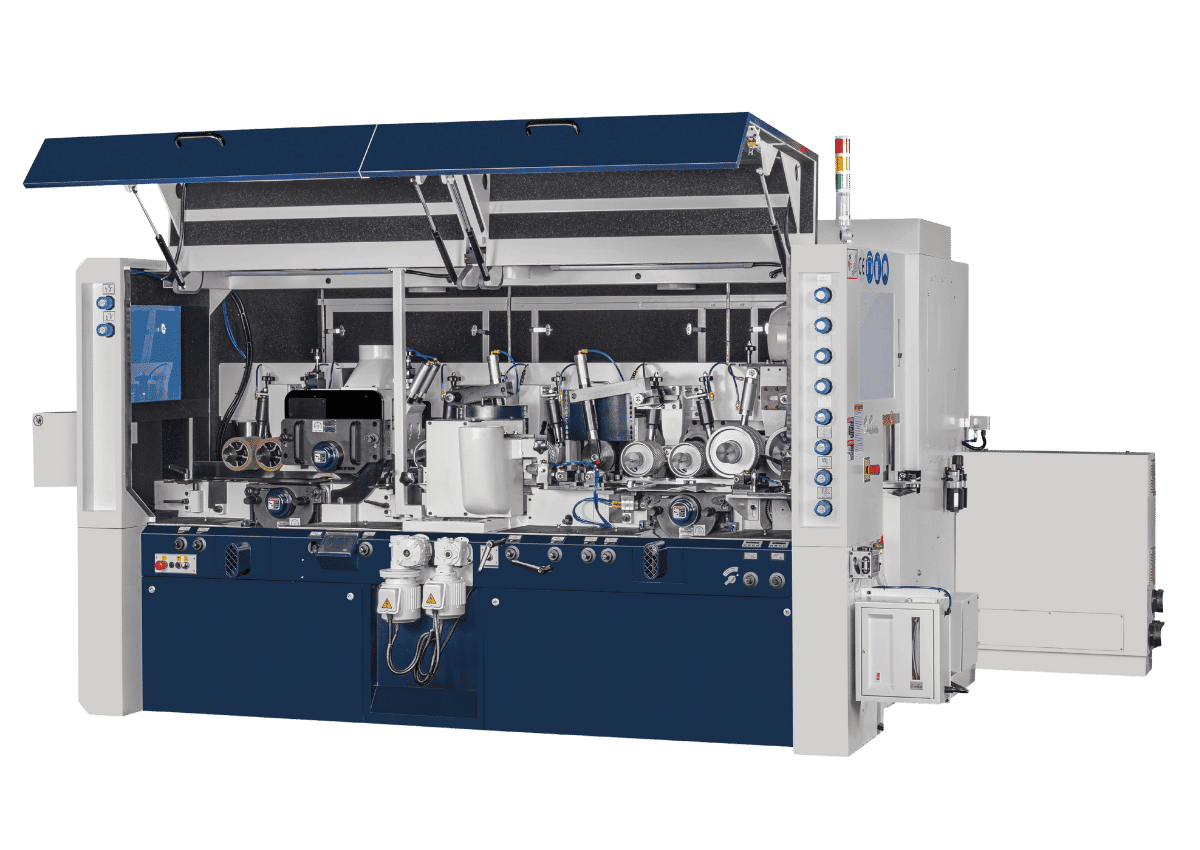

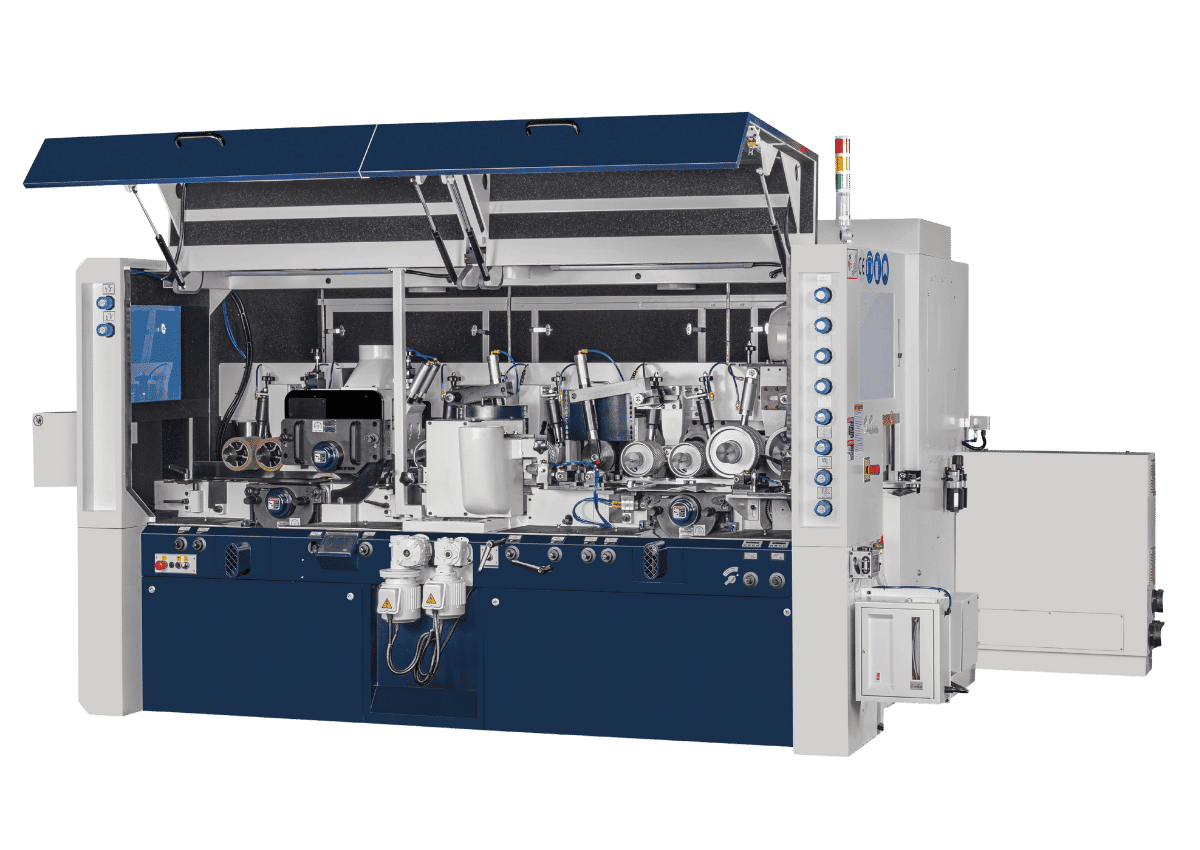

SPEEDMAC 60-120 m/min jointed Moulder

Unbelievable Speed, Unbelievable High Performance and Reliability.

Designed with High Production in Mind

SPEEDMAC 60-120 m/min jointed Moulder

Unbelievable Speed, Unbelievable High Performance and Reliability.

Designed with High Production in Mind

OUTSTANDING FEATURES

- All moulders awarded with CE certification.

- Faster feed speeds of up to 60 meters a minute are standard.

- Programmable controller provides convenient thickness and width of cut settings

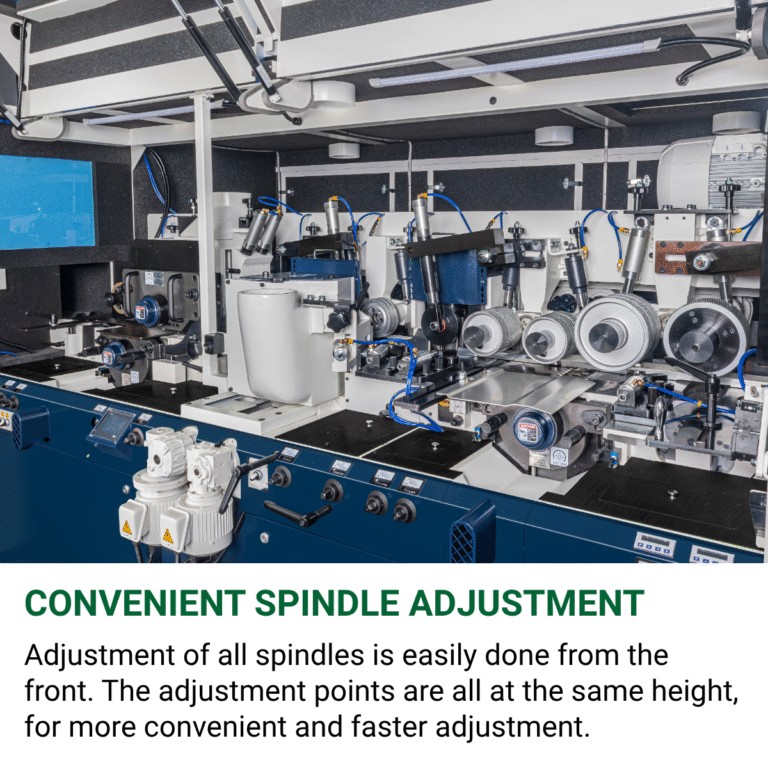

- Adjustment of each spindle can be easily performed using the front adjustment level.

- Exclusive, separate adjustment of the vertical spindles and the feeding table allows the feeding table to be positioned extremely close to the cutterhead to provide added cutting stability.

- The full safety enclosure serves as a chip guard and helps to reduce noise.

- Each spindle is driven by an individual motor for powerful moulding and easy control.

- Automatic lubricator is provided to supply oil to the feeding table.

- One-piece, cast iron or steel welding machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

- Mechanical digital readouts for the pressure elements of top spindle.

- Divided pressure bar in front of top spindle.

- Motorized vertical adjustment of the top spindle including digital readouts.

- Housing bearings for horizontal spindle.

- Straight profile jointer provides accurate operation with high quality finish.

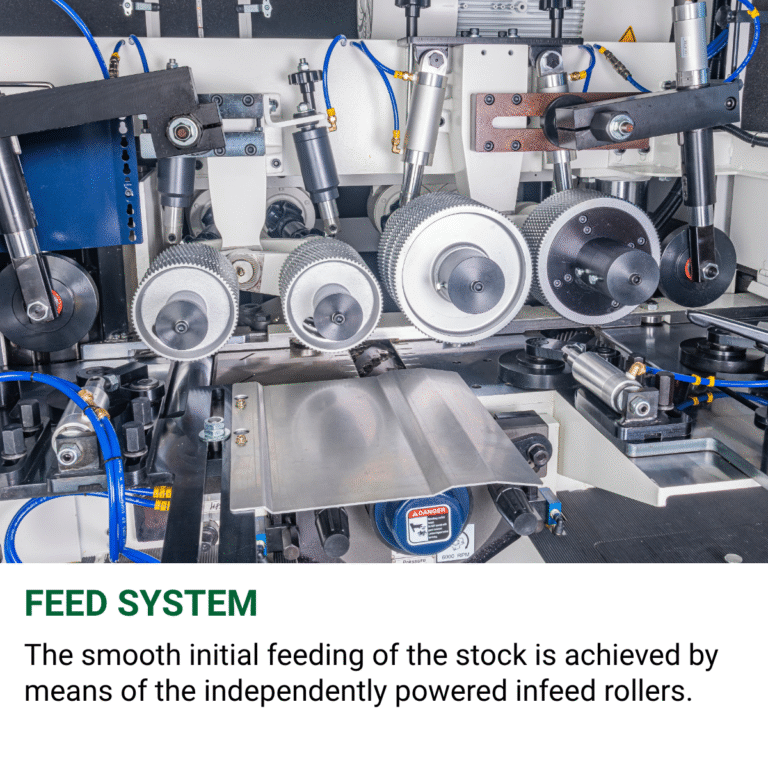

- The powered outfeed rollers provide stable and smooth workpiece outfeed even for especially thin or smooth materials. The rollers remain perfectly parallel even after long-term use.

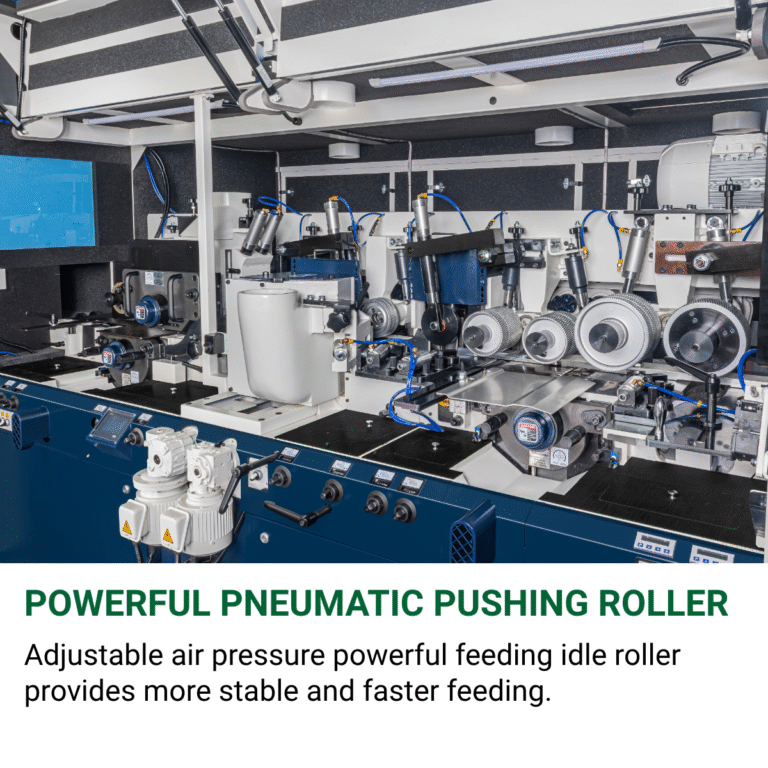

- Multiple pneumatic pressure of the feed rollers can be easily set to provide an outstanding feeding effect.

- Table surface is hard-chrome plated for maximum wear resistance.

- All manually adjusted turning parts are housed in dry bearings for oil-free lubrication.

FEATURES

TECHNICAL SPECIFICATIONS

| STANDARD EQUIPMENT: | Available Options | |

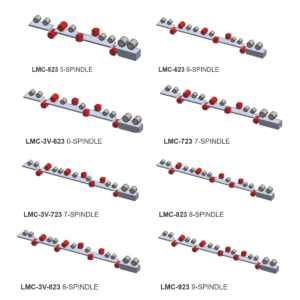

| Number of Heads / Spindles, min-max | 2 to 11 | Any Head Configuration – available |

| Working Width (with a tool cutting circle of 163mm) | 20-230mm (0.78″-9″) | to 310mm (12.2″), 330mm (13″) |

| Working Thickness (with a tool cutting circle of 163mm) | 10-150mm (0.39″-6″) | to 6mm (.25″) to 200 (8″) |

| Basic Spindle Motor capacity – Wye-Delta (Soft Starts) on all motors | 11/12KW (15HP) | to 37.5KW / 50HP |

| Spindle Diameter | 50mm | 1 13/16″ / 2 1/8″ |

| Spindle Speed | 6000 RPM | 7200 / 8000 RPM |

| Tool cutting circle, First Bottom Spindle, min-max | 125-200mm (5″-7.8″) | |

| Tool cutting circle, Vertical Spindles, min-max | 140-250mm (5.5″-9.8″) | |

| Tool cutting circle, Horizontal Spindles, min-max | 140–250mm (5.5″-9.8″) | |

| Feed Motor | 11KW / 15HP / INVERTER | 15 / 18.5KW (20 / 25HP / INVERTER) |

| Feed speed, infinitely variable by frequency (VFD) driven | 6-60 m/min (20 / 200fpm) | 9-120m/min (30-300fpm) |

| Top Infeed Rolls – Diameter | 205.36mm (8″) | |

| other Top Feed Rolls – Diameter | 140mm (5.5″) | |

| Top Feed Roll Width – Multiple Rolls Stacked on each Top Roll Shaft | 50mm (2″) / Roll | |

| Bottom Feed Roll Width | Full Width | |

| Pneumatic pressure for feed rollers, max | 6 bar (85psi) | |

| Adjustment range for Infeed Table (Btm Head Cut) and Edge Jointing Fence | 10mm (.4″) | |

| Adjustment range of vertical spindles (axial) | 80mm (3.2″) | |

| Adjustment range of horizontal spindles (axial) | 40mm (1.6″) | |

| Length of the Infeed / Straightening table | 0.8M (32″) | 1.4 / 2 / 2.5 / 3M (55″ / 78″ / 98″ / 120″) |

| Diameter of Dust Hoods for Vertical & Horizontal Spindles | Ø175mm (6.9″) | |

| Digital Readouts on All Axis of all Heads | Std. | |

| Digital Readouts for the Chip Breaker Shoes & Pressure Shoes | Std. | |

| Full Sound and Safety Enclosure w/ Strobe Free Lighting | Std. | |

| Motorized vertical adjustment of Feed Beam | Std. | |

| Multiple Lateral Pneumatic Pressure Roller opposite first right spindle | Std. | |

| Chainless Extra HD Cardan Shaft Feed System | Std. |

● All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT : | |

| HSK Configuration

Straight &/or Profile Jointers any heads |

Grooved Bed for running very short material |

| Electronic Rotary Encoder Digital Readouts in lieu of mechancial counters | Split Pressure Shoes |

| Extra HD Feedworks; Bottom top Head Configuration for rough materail feeding | Opposed Side Heads |

| Tilting Side Heads | Universal Spindle, tool cutting circle min 125mm, max 200mm |

| Tilting Top Beam, Tilting Feed, Tilting Feedworks, Tilting top Head Chipbreaker Ass’y, Tilting Pressure Plate(s) |

Rip Saw Section with up to 56kw(75HP) Left(Opposite) Hand Feed Inverter Motor Cutterhead Brakes |

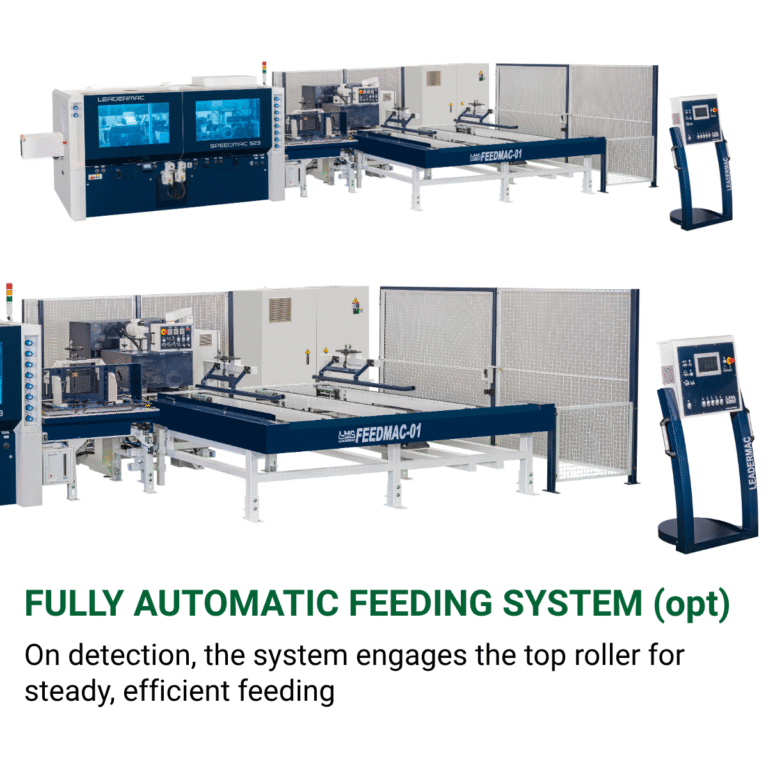

BESPOKE FACTORY OPTIONS

A Wide Range of Spindle Configurations

(other configurations available on request)

CONTROLLERS