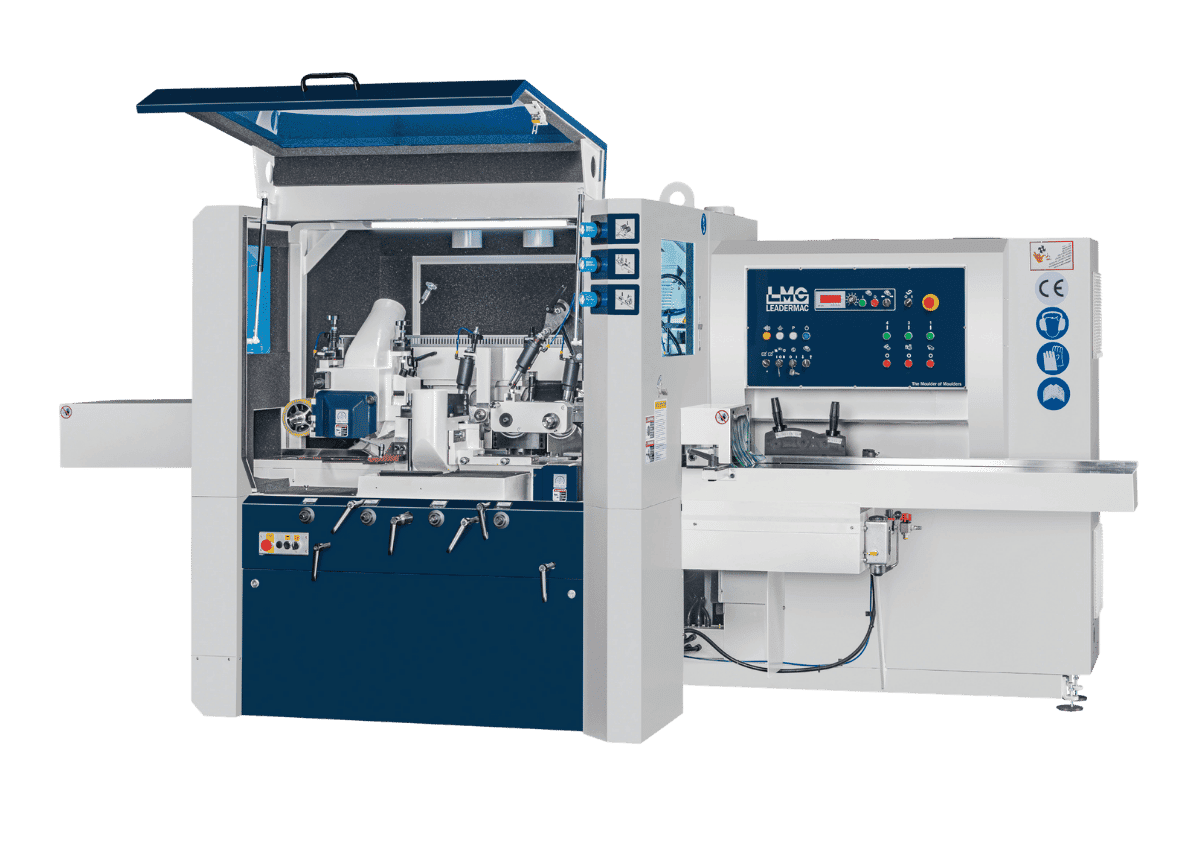

SMARTMAC 4 head Moulder

THE LEADING EDGE IN 4-SIDE FRAME MOULDER

Its cast iron machine frame provides high rigidity and high stability for years of dependable deformation-free operation.

Easy Set Option – IN STOCK IN THE UK

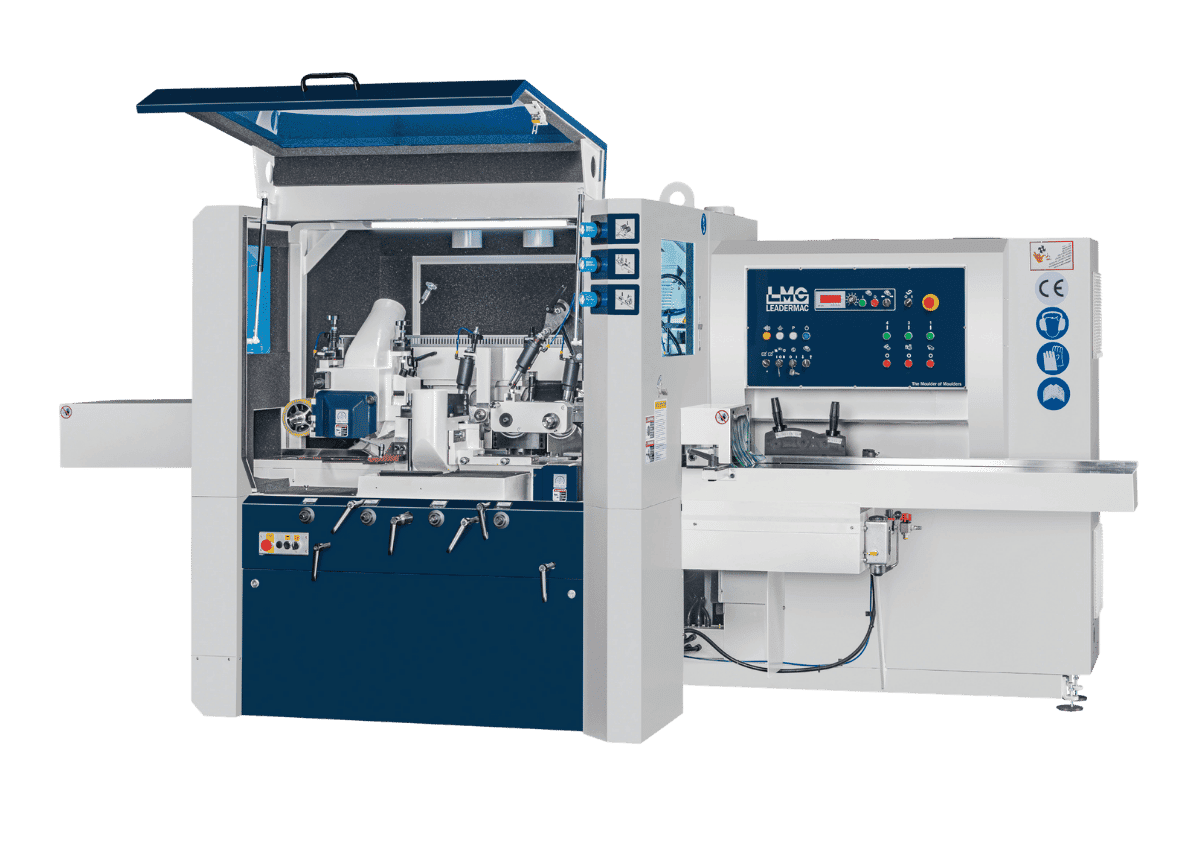

SMARTMAC 4 head Moulder

THE LEADING EDGE IN 4-SIDE FRAME MOULDER

Its cast iron machine frame provides high rigidity and high stability for years of dependable deformation-free operation.

Easy Set Option – IN STOCK IN THE UK

OUTSTANDING FEATURES

- Sound & safety enclosure.

- Feed speeds go up to 24 metres per minute (80 feet per minute)

- The entire machine is covered to reduce noise & safety working environment.

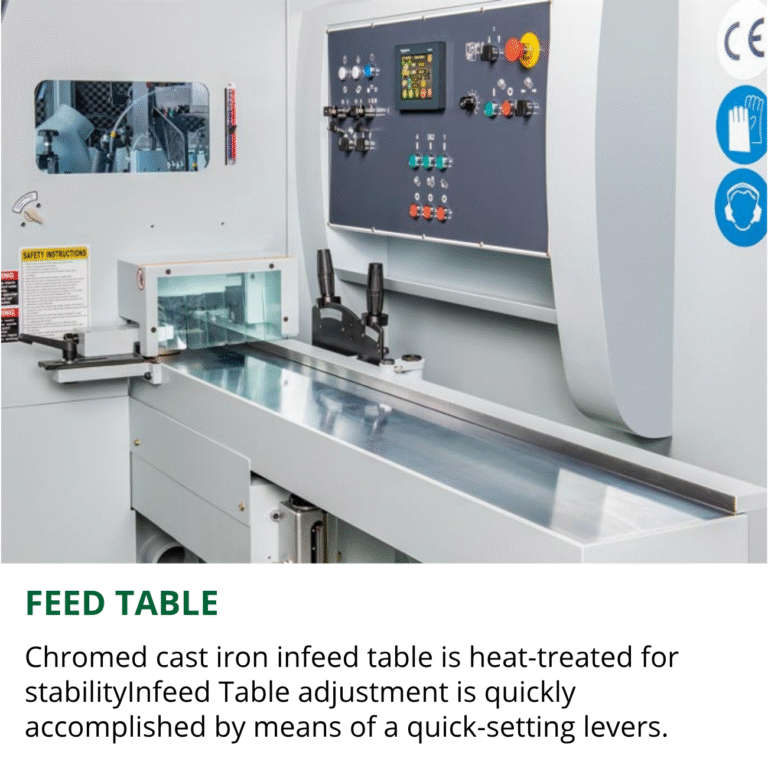

- Harden chromed for entire feeding table.

- 0.3 mm Harden chromed on its surface to last its serving life.

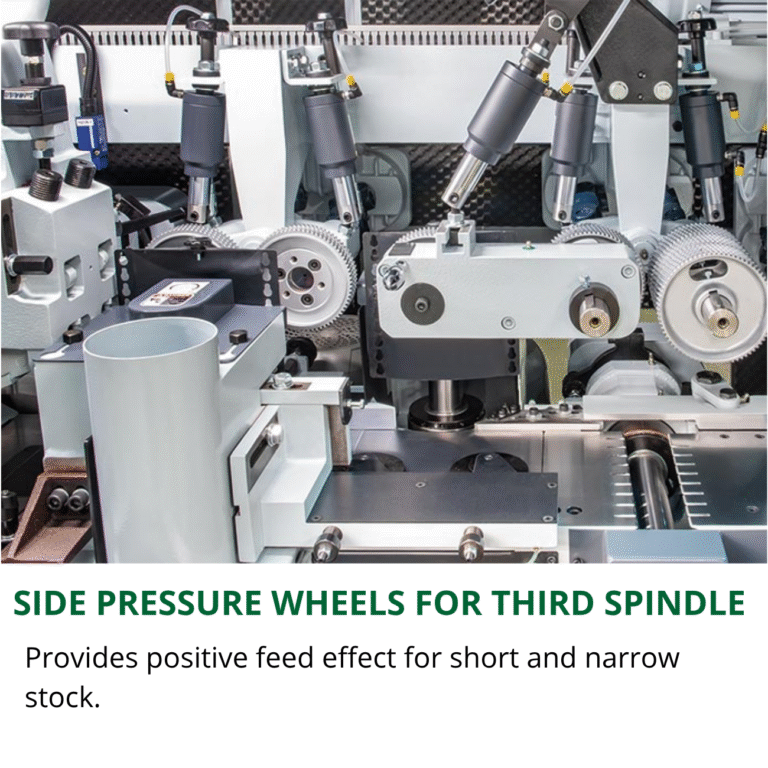

- 3 Stage pressure setting of feed roller.

- Pneumatic roller pressure compensates for large variances in work piece Thickness.

- The max. Air pressure setting is 6 bar.

- Manual oil lubrication for feeding table.

- To supply oil on the 1 point of feeding table.

- 2 meter infeed table.

– Adjustment range for infeed table & edge-jointing fence is 10 mm.

– Infeed fence with reference engraving.

– Without hardened chrome for infeed fence & entire fence. - One piece case iron body.

– Heavy duty elements made of high quality cast metal with optimized - Vibration absorption characteristics are the best for the smooth-running feedwork & spindle performance.

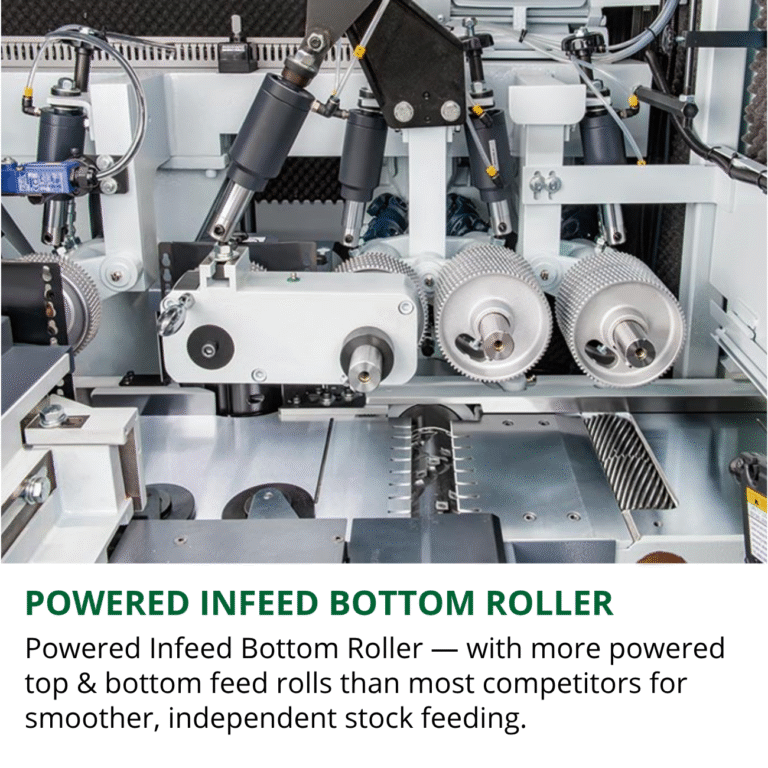

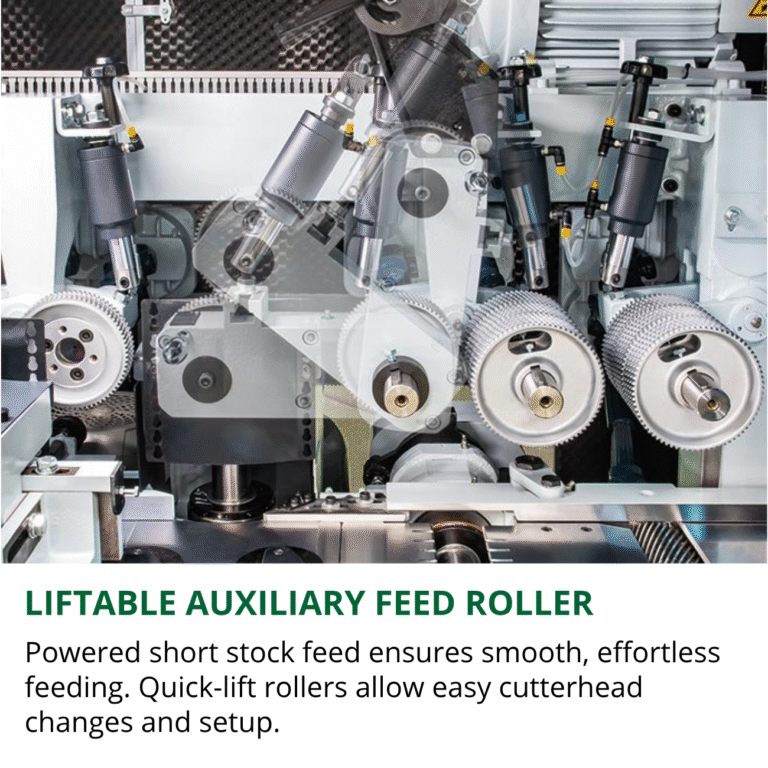

- Power driven upper roller-steel rollers before top spindle, rubber rollers after top spindle under standard spindle arrangement & 2 units of bottom roller are equipped with power driven roller on the feed table.

- Both upper & bottom feed driven by carden universal joint drive with no chains prevent stock-free, more robust, low maintenance, longer service life & more accurate.

- Documentation.

– Maintenance manual, operation manual, electrical diagrams & parts list. - Without cutter tools.

- Tool box.

- To supply “CE” standard for electrical components & machines.

- Motor without mechanical brake

- TE Electrical components

- 2 pcs feed wheel spacers for wide stock holdown

- Infeed fence with reference engraving

- Spindle prepared for standard type.

- Pressure controller for CE machine.

- The cover of machine with hooks for lifting the machine except universal machine.

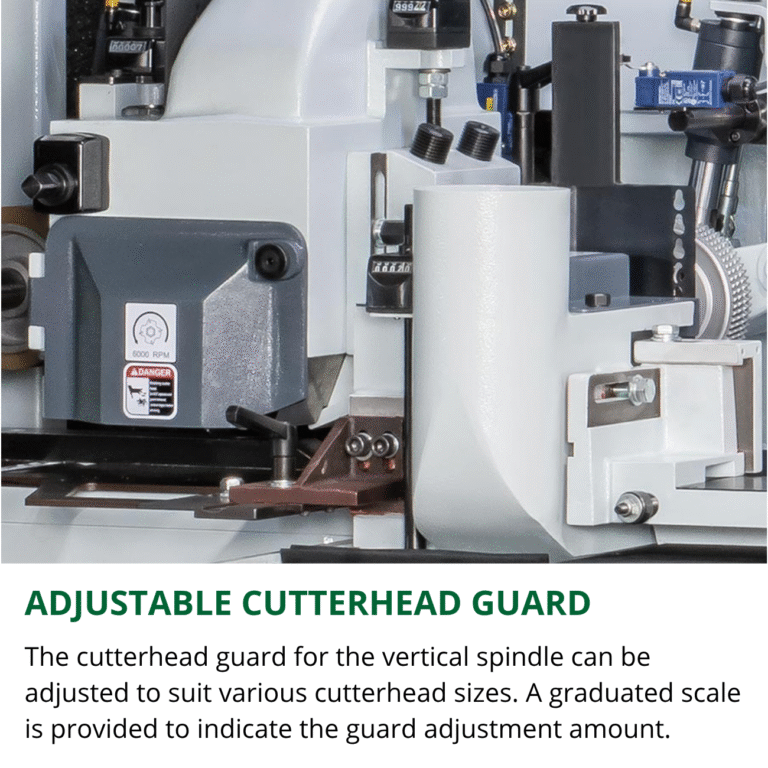

- Adjustment range of vertical spindle (axial) max. 20mm.

- Adjustment range of horizontal spindle (axial) max. 20mm.

FEATURES

TECHNICAL SPECIFICATIONS

& OPTIONS INCLUDED

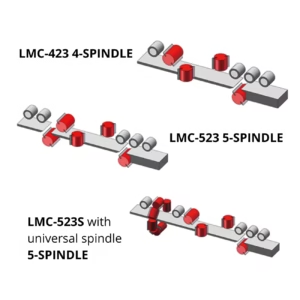

| STANDARD EQUIPMENT: | SMARTMAC 423S |

| Voltage | 50HZ/415V |

| Min/Max working width | 15 mm/230 mm (with a tool cutting circle of 163mm) |

| Min/Max. working Thicknesser | 10 mm/125 mm((with a tool cutting circle of 163mm) |

| Min. length of single work piece | 600mm |

| Min. length of work piece when feed consecutively | 260mm |

| 1st bottom spindle | 7.5HP, allowable cutting circle — 125 – 160 mm |

| 2nd right & 3rd left spindle | 10HP, allowable cutting circle — 112 – 180 mm |

| 4th top spindle | 7.5HP, allowable cutting circle — 112 – 200 mm |

| UP & DOWN motor | 1/2 HPx1 |

| Feed Motor | 5 HP/inverterx1 |

| Spindle diameter

Spindle R.P.M Feed speed |

40 mm

6,000 RPM 6-24m/min |

* All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT: | |

| Transporting machine by hanging rings | |

| Infeed fence with hardened chrome | |

| 1st Spindle | 230 mm (L) – 240 MM (L) |

| 1st, 4th spindle motor use inverter brake | instead of mechanical brake for motor 7.5HP (380v-500v) |

| 2nd & 3rd spindle motor use inverter brake | instead of mechanical brake for motor 7.5HP (380v-500v) |

| Shielding cable for inverter 7.5HP/10HP | for 1st, 2nd & 3rd, 4th spindle |

| The dust hold 5″ on the sound enclouse for | 4 spindle machine |

| The dust hold 5″ on the sound enclosure | for 4 spindle machines |

| General grease gun | Red grease NO.2 |

| Key-operated switch for set up | mode/manual/mode automatic mode |

| Circuit breaker of transformer | use D type instead of standard C type |

| Pressure control | for air pressure – CE regulation |

| Schneider touch screen EASYSET (beam x 1 + NC X 2) |

|

| 3R & 4R use one same LCD display | |

| COOLING FAN | 10″ |

| Circuit breaker of transformer use D type | instead of standard C type |

BESPOKE FACTORY OPTIONS

SPINDLES

CONTROLLER