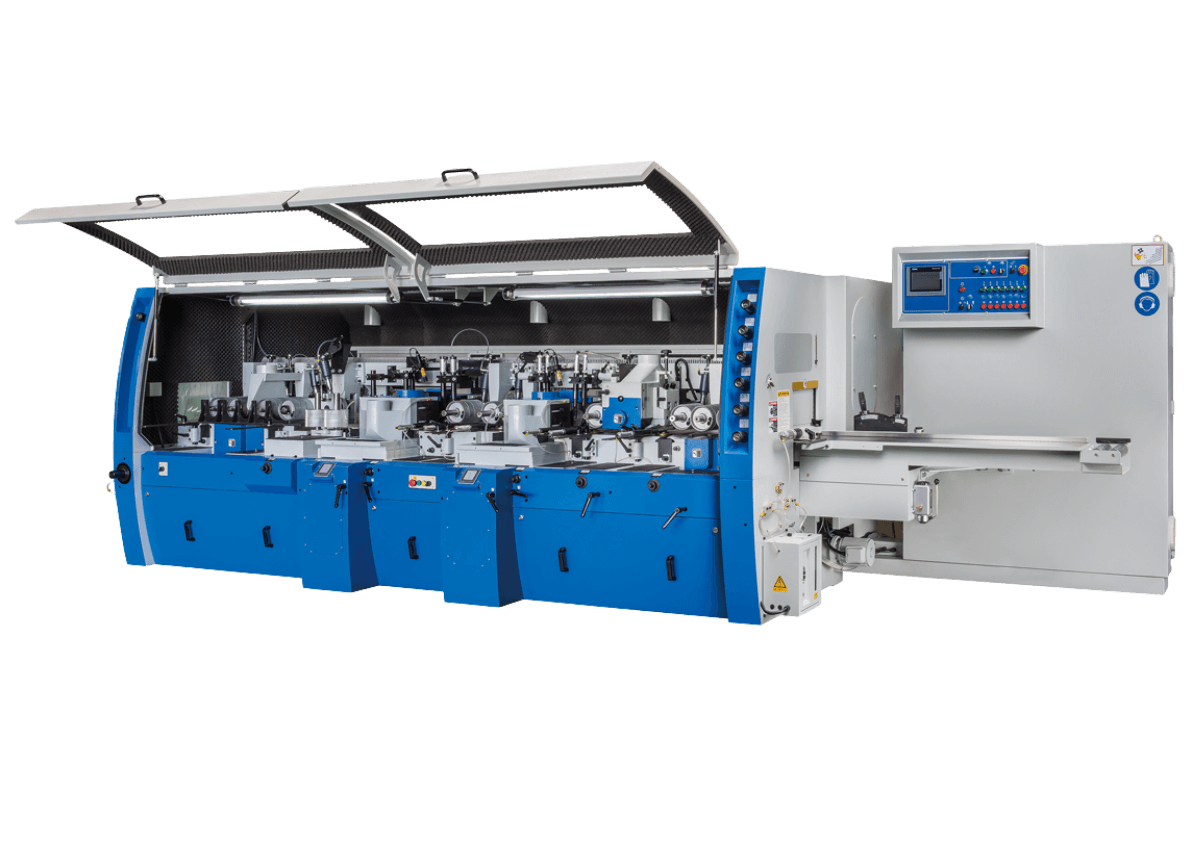

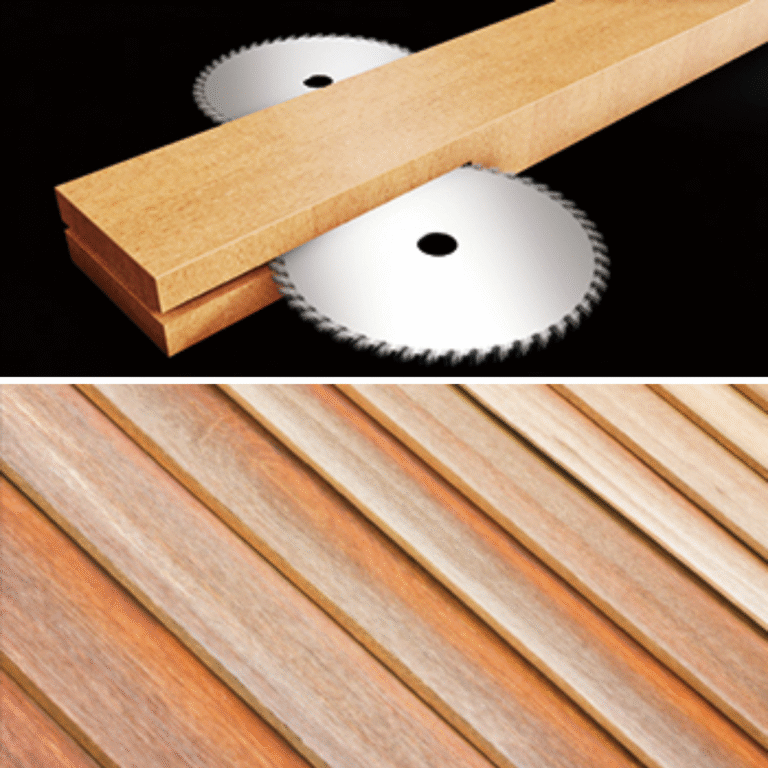

Slicermac Vertical Rip Saw

With Speed and Versatility to Boost Your Productivity. With fine features to give you the winning edge in 4 side moulding.

4-Side Moulder With Slicing Units

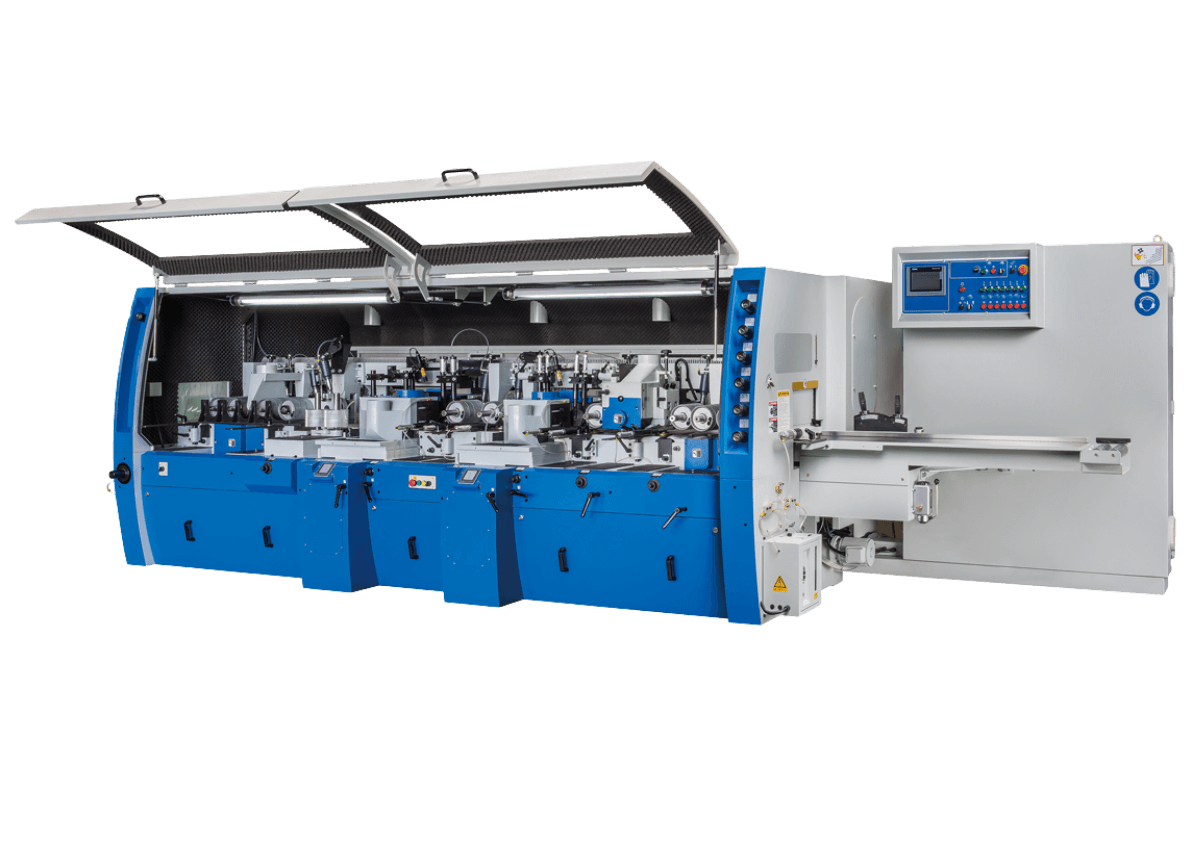

Slicermac Vertical Rip Saw

With Speed and Versatility to Boost Your Productivity. With fine features to give you the winning edge in 4 side moulding.

4-Side Moulder With Slicing Units

OUTSTANDING FEATURES

- Various spindle configurations available.

- Unique chainless cardan shaft transmission for upper and lower rollers.

- Ruggedly constructed for high rigidity and superior performance.

- Hard-chromed table for maximum resistance and durability.

- Full sound and safety enclosure.

- Motorized roller for vertical adjustment.

- Lateral pressure roller for opposite first right spindle.

- Chainless cardan feed system.

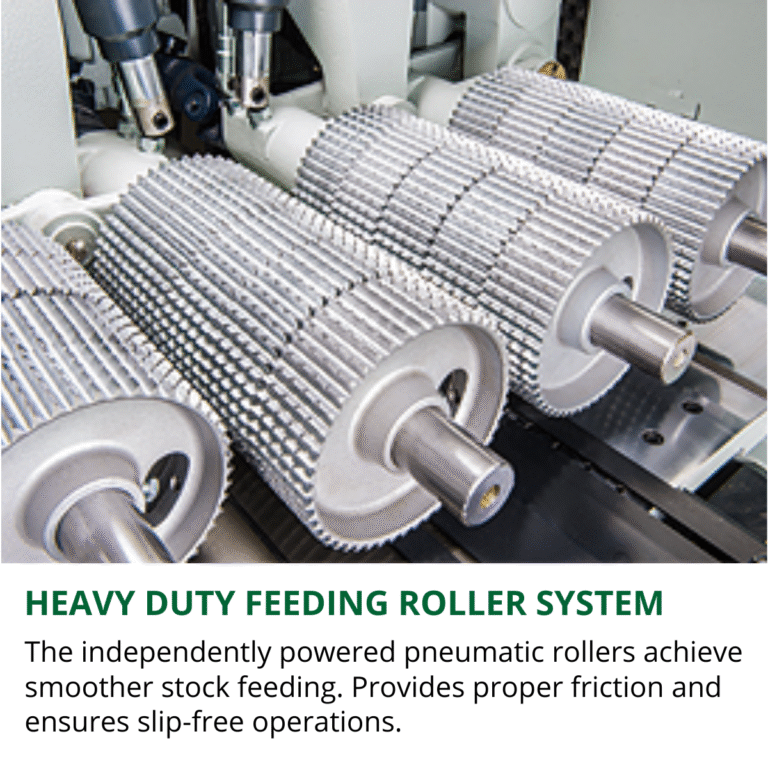

- Independently powered pneumatic rollers for variable thickness feeding.

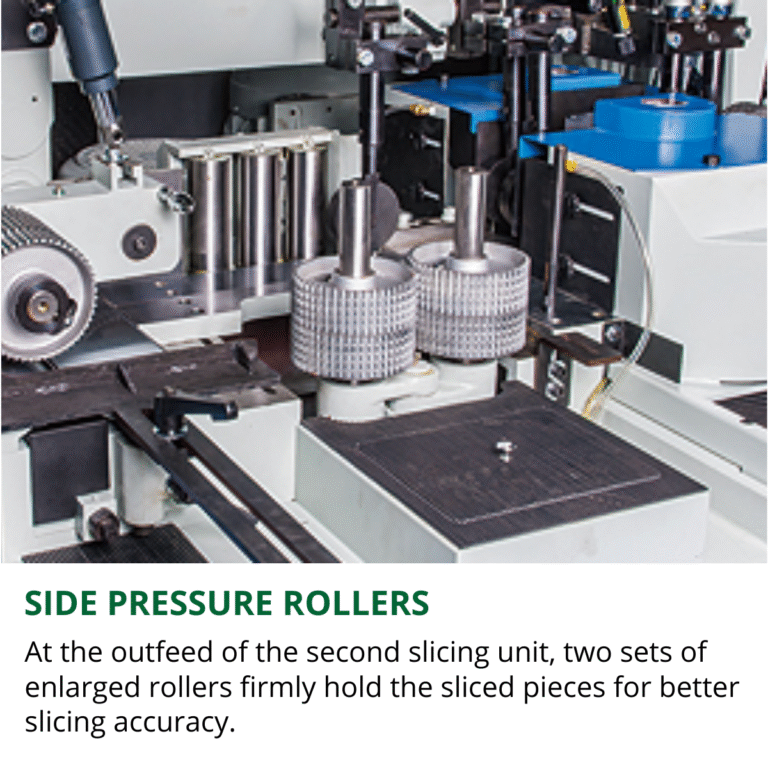

- The enlarged rollers ensure smooth and slip-free operations.

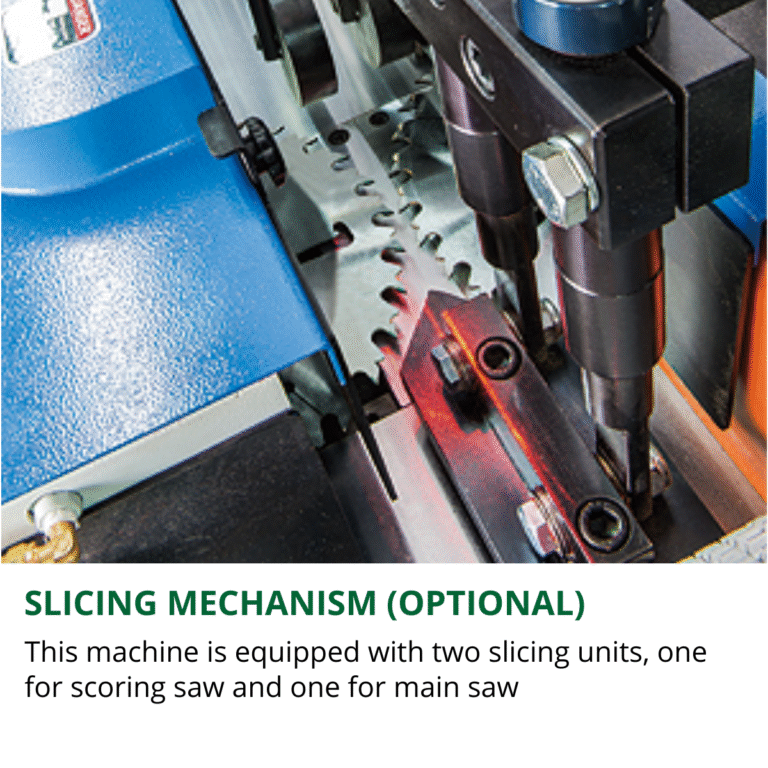

- 1 multi-rip saw available on the last horizontal spindle for precise ripping (Optional).

- Equipped with 2 slicing units (Scoring + main saw) for better slicing quality.

- Easy spindle adjustment with front levers.

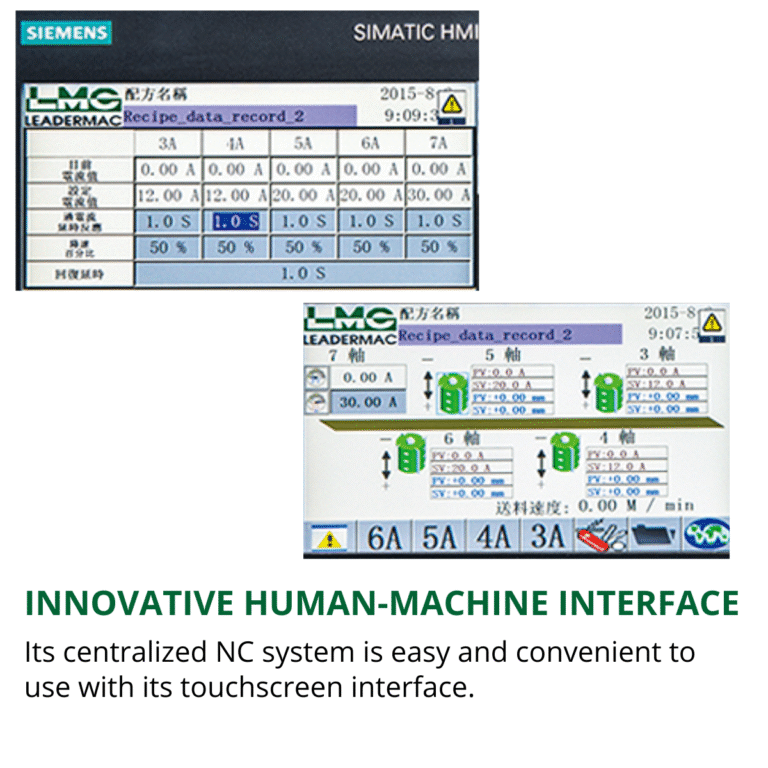

- Independently powered spindle for easy control.

- Fast feeding speed (Standard: 24m/min ; Optional: 36m/min).

- Full safety enclosure with noise reduction.

- The pressure gauges are mounted on the front side for easy adjustment

FEATURES

TECHNICAL SPECIFICATIONS

| LMC-223 to LMC-823: | |

| Working width for moulding (at a cutting circle of 163mm) | 230 mm |

| Working height for moulding (at a cutting circle of 163mm) | 10 – 150 mm |

| Working width for VM | 200 mm |

| Working height for VM | 100 mm |

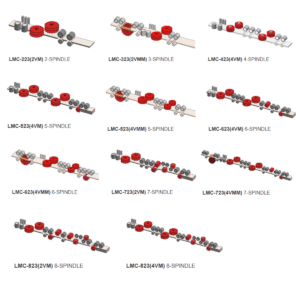

| Number of spindles, min-max. | 2 – 8 |

| Basic motor capacity per spindle | 5.5 KW / 7.5 HP |

| Basic motor capacity of feed | 4 KW / 5 HP / Inverter |

| Spindle speed | 6000 RPM for moulding spindle, 4000 RPM for multiple rip saw spindle |

| Spindle diameter | 40 mm for moulding spindle, 50 mm for multiple rip saw spindle |

| Tool cutting circle (first bottom spindles) min-max. | 125 – 160 mm |

| Max. saw blade cutting circle (1st slicing unit) | 250 mm |

| Max. saw blade cutting circle (2nd slicing unit) | 300 mm |

| Tool cutting circle (top horizontal spindles) min-max. | 112 – 200 mm |

| Tool cutting circle (bottom horizontal spindles) min-max. | 112 – 200 mm |

| Infinitely variable feeding speed controlled by VFD Device | 6 – 24 m/min |

| Feed roller diameter | 140 mm |

| Feed roller width | 50 mm |

| Max. pneumatic pressure for feed rollers | 6 kg/cm² (87psi) |

| Adjustment range for infeed table and edge of jointing fence | 10 mm |

| Adjustment range of vertical spindles (axial) | 30 mm |

| Adjustment range of horizontal spindles (axial) | 20 mm |

| Adjustment range of vertical spindles for slicing units (axial) | 5 mm |

| Length of straightening table | 2 m |

* All specifications, dimensions and design characteristics are subject to change without notice.

BESPOKE FACTORY OPTIONS

A Wide Range of Spindle Configurations

(other configurations available on request)

Option Equipment:

- Tool setting and measuring devices.

- Increased horsepower.

- CE specifications.

- Fast feeding speed up to 36m/min.

- Cooling system for slicing units.

- Motor with inverter control for slicing units.

- Bottom multi-rip saw unit.

- Clamping system.

- Working width up to 310mm is available