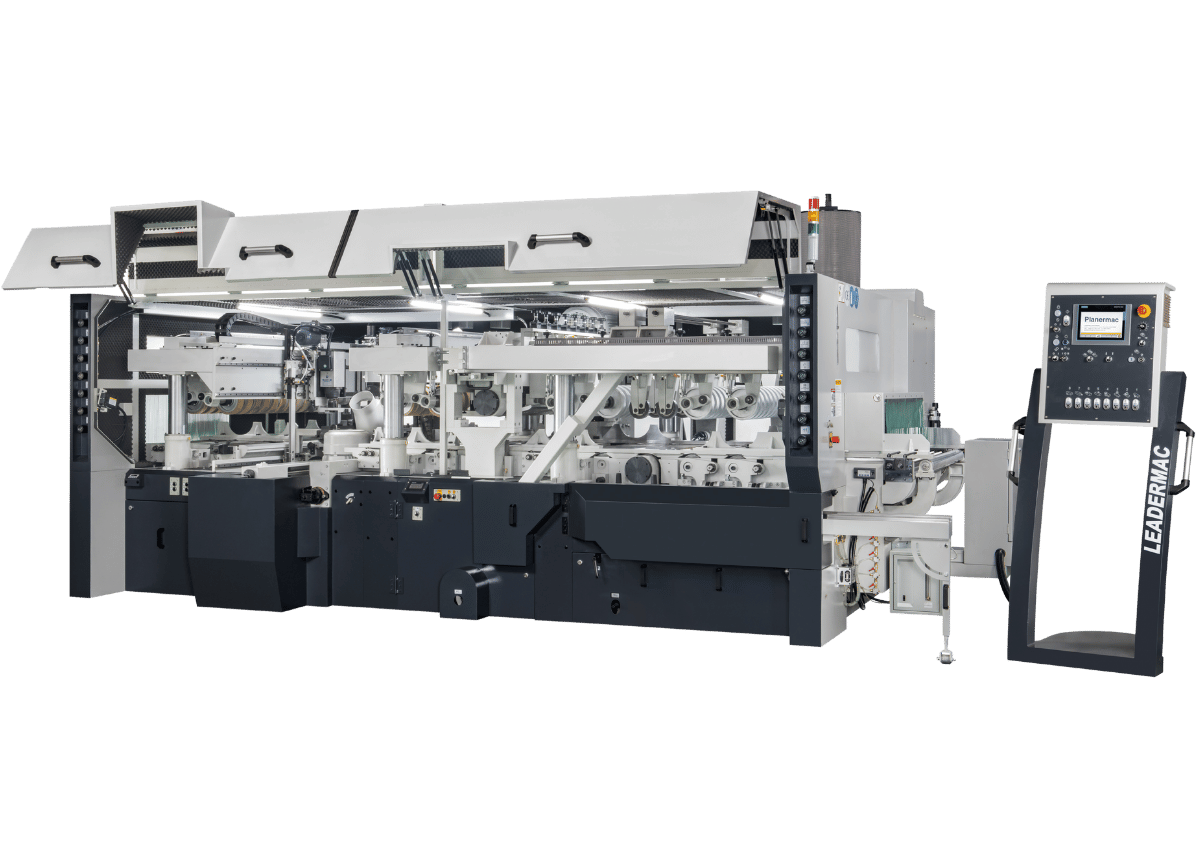

PLANERMAC 1300 mm Width Moulder

Leadership through Performance and Reliability

Work width: 1300mm

PLANERMAC 1300 mm Width Moulder

Leadership through Performance and Reliability

Work width: 1300mm

OUTSTANDING FEATURES

- Sound and safety enclosure – The entire machine is covered to reduce noise and improve safety

- Hardened chrome feeding table – 0.3mm hardened chrome surface to increase service life

- 3 Stage pressure setting of feed roller – Pneumatic roller pressure compensates for large variances in workpiece thickness. Max. air pressure setting is 6 bar

- Automatic oil lubrication for feeding table – Supplies oil on the 2 points of feeding table with timer control

- 1.4 meter infeed table

- Adjustment range for infeed table and edge-jointing fence is 10mm.

- Infeed fence with non-reference engraving

- Steel body

- Power driven upper roller – Steel rollers before top spindle, rubber rollers after top spindle under standard spindle arrangement & 5 units of bottom roller are equipped with power driver roller on the feed table.

OUTBOARD BEARING SUPPORT ON HORIZONTAL SPINDLE

The horizontal spindle is equipped with outboard bearing support, providing solid support.

POWER DRIVEN UPPER ROLLERS

Steel rollers before the top spindle and rubber rollers after the top spindle are designed for standard spindle arrangement.

POWER DRIVE BOTTOM ROLLERS

5 units of bottom

FEATURES

TECHNICAL SPECIFICATIONS

| STANDARD EQUIPMENT / Planermc – LMC 245PL to LMC11106PL | Standard Base Equipment | Available Options |

| Number of Spindles, min-max | 2 to 11 | Special Machine Configurations on request |

| Working Width (at a tool cutting circle of 125mm-200mm) | 15~40mm (0.59″~17.7″) | 500mm (20″) ; 600mm (24″) ; 700mm (27.5″) ; 1300mm (51.1″) |

| Working Thickness (at a tool cutting circle of 125mm-200mm) | 10~200mm (0.39″~7.1″) | to 200mm (8″) ; to 250mm (10″) ; to 300mm (12″) ;or to 350mm (14″) |

| Basic Spindle Motor capacity (Wye Delta Soft Starts on All Motors) | 11 KW / 15HP | to 75KW (100HP) |

| Spindle Speed | 5500 RPM | 6000 RPM or 7200 RPM |

| Spindle Diameter | 50mm (2″) | 1 13/16″ or 2 1/8″ |

| Tool Cutting Circle,1st Bottom Spindle, min-max | 125~180mm (5″~7.1″) | |

| Tool Cutting Circle, Vertical Spindles, Left, min-max | 125~200mm (5″~8″) | to 250mm (10″) |

| Tool Cutting Circle, Vertical Spindles, Right, min-max | 125~200mm (5″~8″) | to 250mm (10″) |

| Tool Cutting Circle, Horizontal Spindles, Top, min-max | 125~200mm (5″~8″) | to 250mm (10″) |

| Tool cutting circle, Horizontal Spindles, Bottom, min-max | 125~200mm (5″~8″) | to 250mm (10″) |

| Feed Motor | 3.7 KW / 5HP / INVERTER | to 15kw (25 HP) |

| Feed Speed, infinitely variable by VFD Inverter duty Motor | 6~24 m/min (20~80FPM) | to 36mpm (120fpm) ; 48mpm (160fpm) ; 60mpm (200fpm) or 90mpm (300fpm) |

| Top Feed Roller Diameter | 200mm (8″) | |

| Top Feed Roller Width | 4 x 50mm (2″) | |

| Pneumatic Pressure for feed rollers, max | 6 bar (85psi) | |

| Adjustment range for infeed table and edge-jointing fence | 10mm (0.4″) | |

| Adjustment range for vertical spindle (axial) | 40mm (1.57″) | |

| Adjustment range for horizontal spindle (axial) | 20mm (0.78″) | |

| Length of the Infeed Straightening Table | 1.4M (55″) | 1M (39″) ; 2M (78″) ; 2.5M (98″) or 3M (120″) |

| Mechanical digital readouts for the pressure shoes & hold-down unit | Included | |

| Full Sound and Safety Enclosure w/ Strobe-free Lighting | Included | Extra Insulation with Steel Punched Sheet Steel Ineterior |

| Motorized vertical adjustment of Feed Beam | Included | |

| Pneumatic Lateral Pressure Roller System opposite first right spindle | Included | |

| Extra HD Chainless Cardan Shaft Feed System w/ExHD Gearboxes | Included | |

| Quick Set Setworks on Near Side Head (s) & Top Heads (Radial Set) | Included | optional on all Axis and SmartSet Controls as noted Below optional |

● All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT : | |

| To CE Standards | Setting and Measuring Devices for the grinding room |

| Chanfering Heads for Material Corners | SINGLE Digital Readout and Quick Set to Main guide & Infeed Rolls-table |

| Straight &/or Profile Jointers any heads | (1, 1.4 & 2M Table) |

| Tilting Side Heads | Additional Quick Set Setworks on any desired Cutterhead Axis |

| Split Pressure Shoes | Outboard Top Feed roll Bearing Supports (optional on 450mm machine – Std. on all other |

| Directly Opposed Side Heads | machines |

| Rip Saw Section with up to 75kw (100HP) | Electronic Rotary Encoder Digital Readouts in lieu of mechancial counters – not required |

| Left (Opposite) Hand Feed | with SmartSet Controls as included |

| Inverter Motor Cutterhead Brakes | Hydro-Loc Outboards for Side Head Shafts that are 300mm(12″) or 350mm(14″) long |

| Cutterhead Lift Off Crane | |

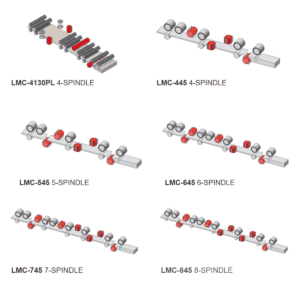

BESPOKE FACTORY OPTIONS

Wide Range of Spindle Configurations

(other configurations available on request)

Controllers