COMPACT 6 Head Moulder

LEADINGSHIP THROUGH PERFORMANCE & RELIABILITY

These Compact, Cost-effective 4-side Moulders Enable Amazingly High Stability, Performance & Precision Moulding.

Standard & Easy Set Option – IN STOCK IN THE UK

COMPACT 6 Head Moulder

LEADINGSHIP THROUGH PERFORMANCE & RELIABILITY

These Compact, Cost-effective 4-side Moulders Enable Amazingly High Stability, Performance & Precision Moulding.

Standard & Easy Set Option – IN STOCK IN THE UK

OUTSTANDING FEATURES

- All moulders are CE certified to meet safety standards.

- The machine has a one-piece cast iron frame that is heat treated for extra strength and stability.

- Feed speeds go up to 24 metres per minute (80 feet per minute).

- You can adjust every spindle except the last bottom one using front-mounted levers.

- Each spindle has its own motor for strong power and easy control.

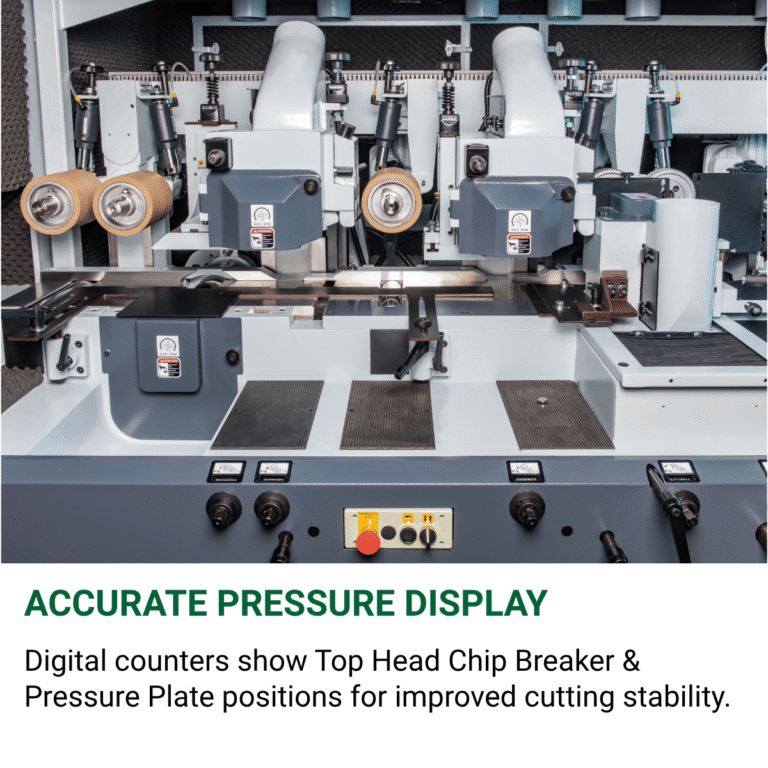

- The pressure on the top feed rollers is easy to adjust for smooth feeding.

- Tables have a hard chrome surface for wear resistance.

- All moving parts that need adjusting have permanently greased bearings — no oiling needed.

- The enclosure keeps chips and pieces inside and helps reduce noise.

- Oil can be added manually to one point on the feeding table.

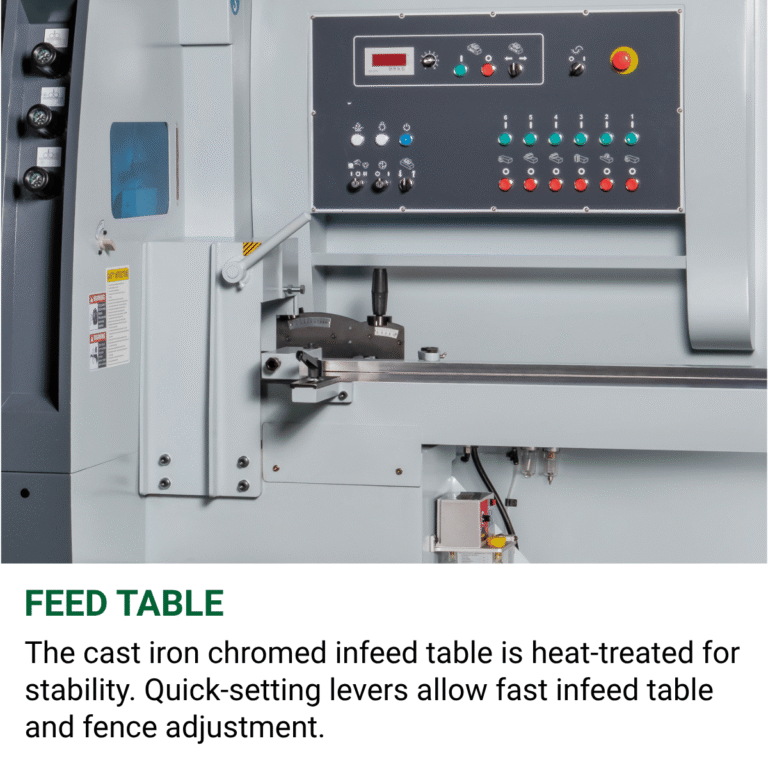

- The infeed table and edge-jointing fence can be adjusted by 10 mm.

- The infeed fence has engraved markings for easy positioning.

- The fences are not hard-chrome plated.

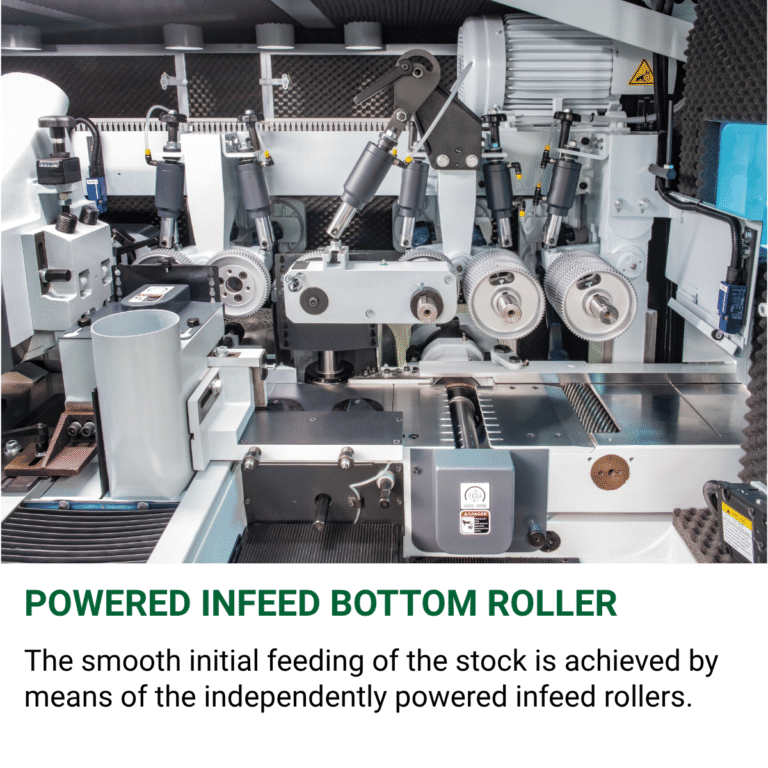

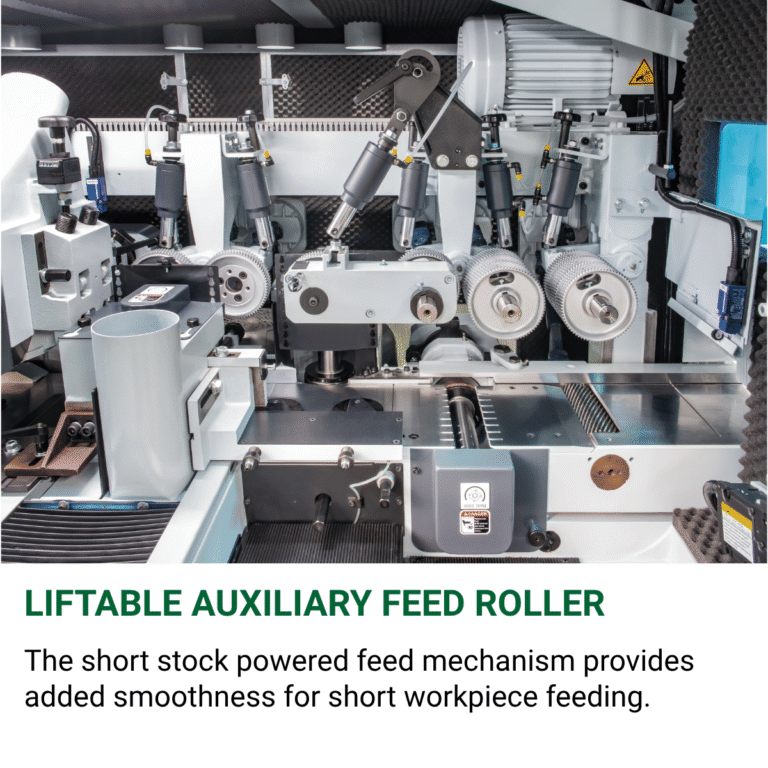

- Steel rollers before the top spindle, rubber rollers after, and three power-driven bottom rollers.

- Rollers are driven by universal joints — no chains — for less maintenance and better accuracy.

- Spindles use standard-speed bearings for steady running.

- Includes manuals for maintenance, operation, electrical diagrams, and parts lists.

- Cutter tools are not included.

- Toolbox is included

- Pressure controller for CE machines.

- Machine cover with lifting hooks comes standard on CE models (except universal machines).

- Vertical spindle can move up to 60 mm.

- Horizontal spindle can move up to 20 mm.

FEATURES

TECHNICAL SPECIFICATIONS

SPECIFICATIONS & OPTIONS INCLUDED

| STANDARD EQUIPMENT: | LMC-623C COMPACT + EASYSET |

| Min. working width | 15 mm |

| Max. working width | 230 mm (with a tool cutting circle of 163 mm) |

| Min. working thickness | 10 mm |

| Max. working thickness | 150 mm (with a tool cutting circle of 163 mm) |

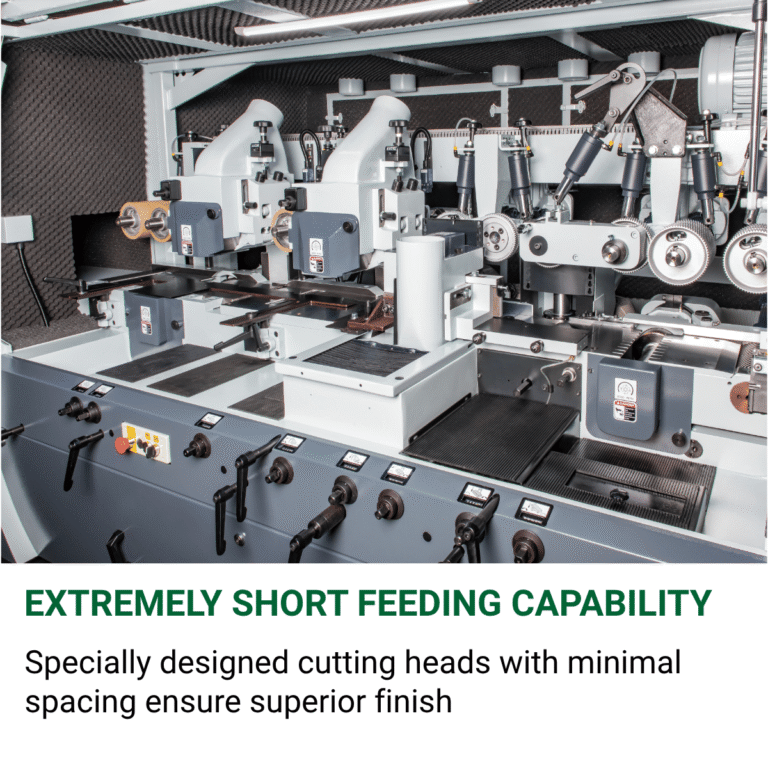

| Min. length of single work piece | 800 mm |

| Min. length of work piece (fed consecutively) | 300 mm |

| 1st bottom spindle | 10 HP, allowable cutting circle: 125–160 mm |

| 2nd right spindle | 10 HP, allowable cutting circle: 112–200 mm |

| 3rd left spindle | 10 HP, allowable cutting circle: 112–200 mm |

| 4th top spindle | 15 HP, allowable cutting circle: 112–200 mm |

| 5th top spindle | 15 HP, allowable cutting circle: 112–200 mm |

| 6th bottom spindle | 15 HP, allowable cutting circle: 112–200 mm |

| SOME OPTIONAL EQUIPMENT: |

| HSK Configuration

Infeed fence with hardened chrome |

| 63mm high fences after right spindle instead of standard fences |

| 1st Spindle 230mm(L) → 240mm(L) (no charge) |

| 60mm axial adjustment (vertical stroke) for each vertical spindle (3 & 4) (no charge) |

| Pneumatic chipbreaker on top spindle (spindle 4, 5) |

| Extra tables for moulding and multiple rip saw at the last bottom spindle for 230mm wide machine, including: 1 pce of table plate, 1 pce of table plate, 1 pce of fibre plate, 1 set of pressure plate with fibre |

| Mechanical digital readout for horizontal adjustment of second bottom head adjusted from front side of the machine |

| Antikickback device for splitting |

| The dust hole 5″ on the sound enclosure for 6 spindle machine |

| General grease gun |

| SCHNEIDER TOUCH SCREEN EASYSET (Beam x 1 + NC x 3) – Schneider 10.1″ HMI (MEMORY 200 SETS) – Schneider PLC – Motorized Axes: derived by MCC (Magnetic Contact Switch), transmitted by General Screw, feedback by Proximity Sensor – Profile data (200 sets) – 3 NC controls for 3R, 4R, 5R spindle – 1 NC control for the height of the feed beam |

| Aux. HMI display for 3R |

| Circuit breaker of transformer use D type instead of standard C type |

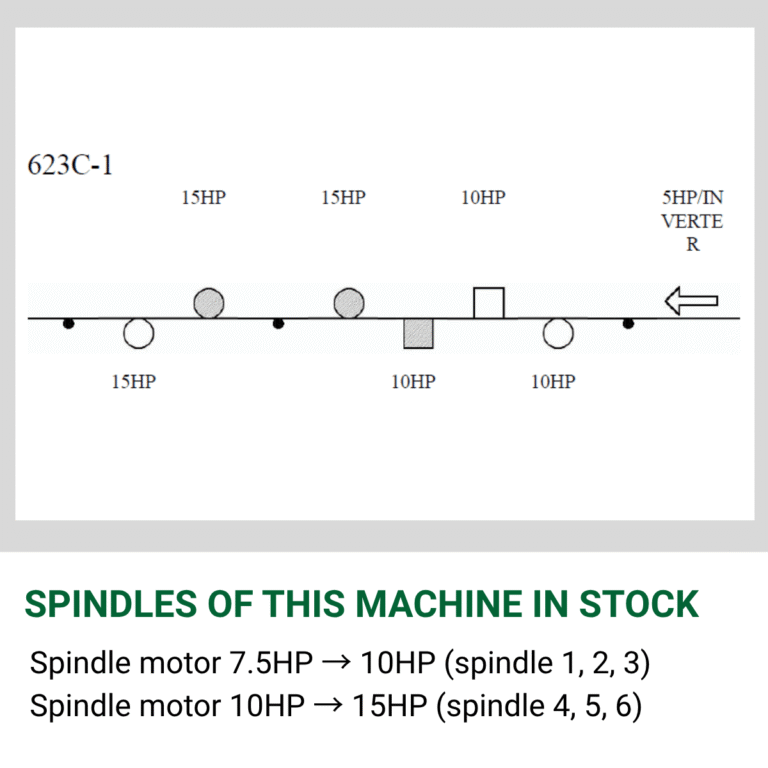

| Spindle motor 7.5HP → 10HP (spindle 1, 2, 3) |

| Spindle motor 10HP → 15HP (spindle 4, 5, 6) |

| Spindle motor use inverter brake instead of mechanical brake for motor 10HP (380V~500V) (spindle 1, 2, 3) |

| Spindle motor use inverter brake instead of mechanical brake for motor 15HP (380V~500V) (spindle 4, 5, 6) |

| Cooling fan 10″ |

| Shielding cable for inverter 7.5HP/10HP (spindle 1, 2, 3) |

| Shielding cable for inverter 15HP/20HP (spindle 4, 5, 6) |

| 1st spindle with spiral cutting tool φ125*φ40*9″*6T |

| Vertical spindle with H.S.S loose knives φ125*φ40*155mm*4T |

| Horizontal spindle with H.S.S loose knives φ125*φ40*230mm*4T |

BESPOKE FACTORY OPTIONS

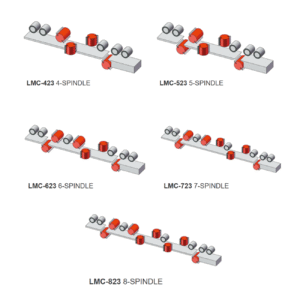

A Wide Range of Spindle Configurations (other configurations available on request)

CONTROLLER