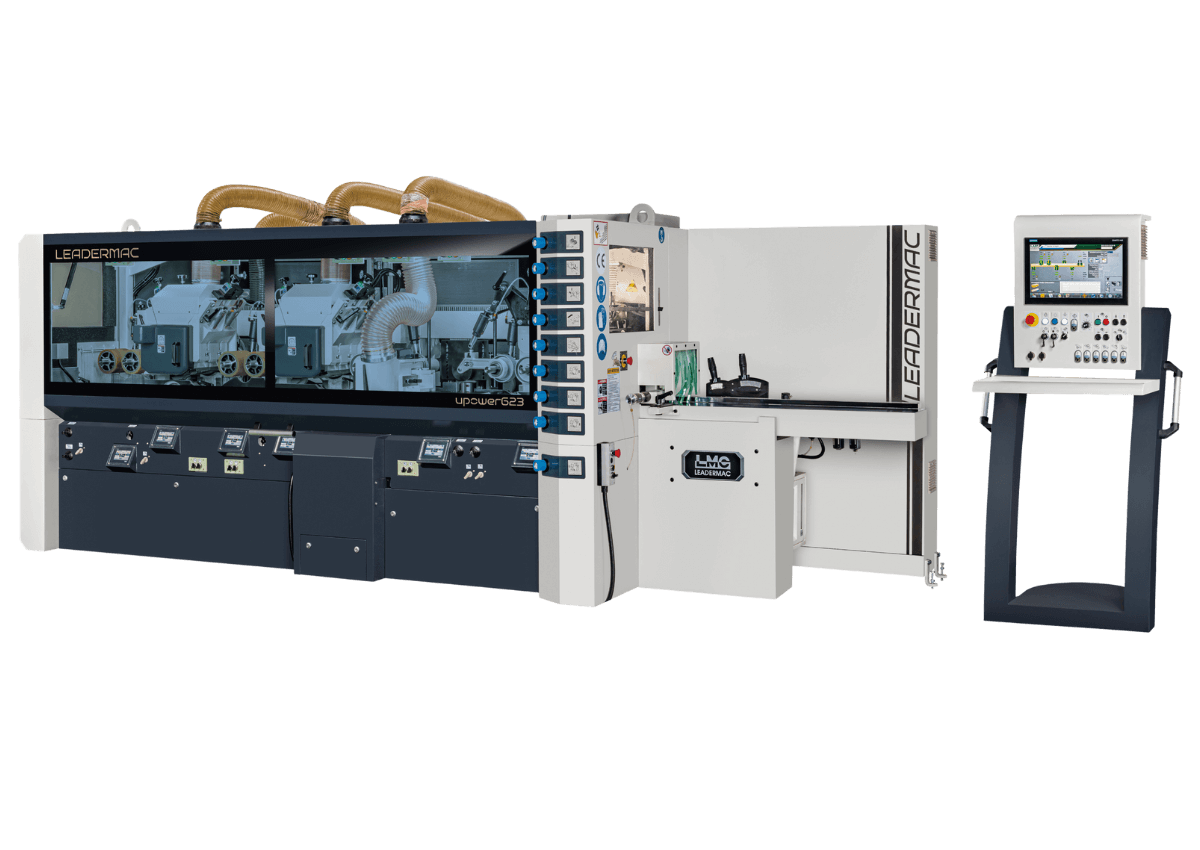

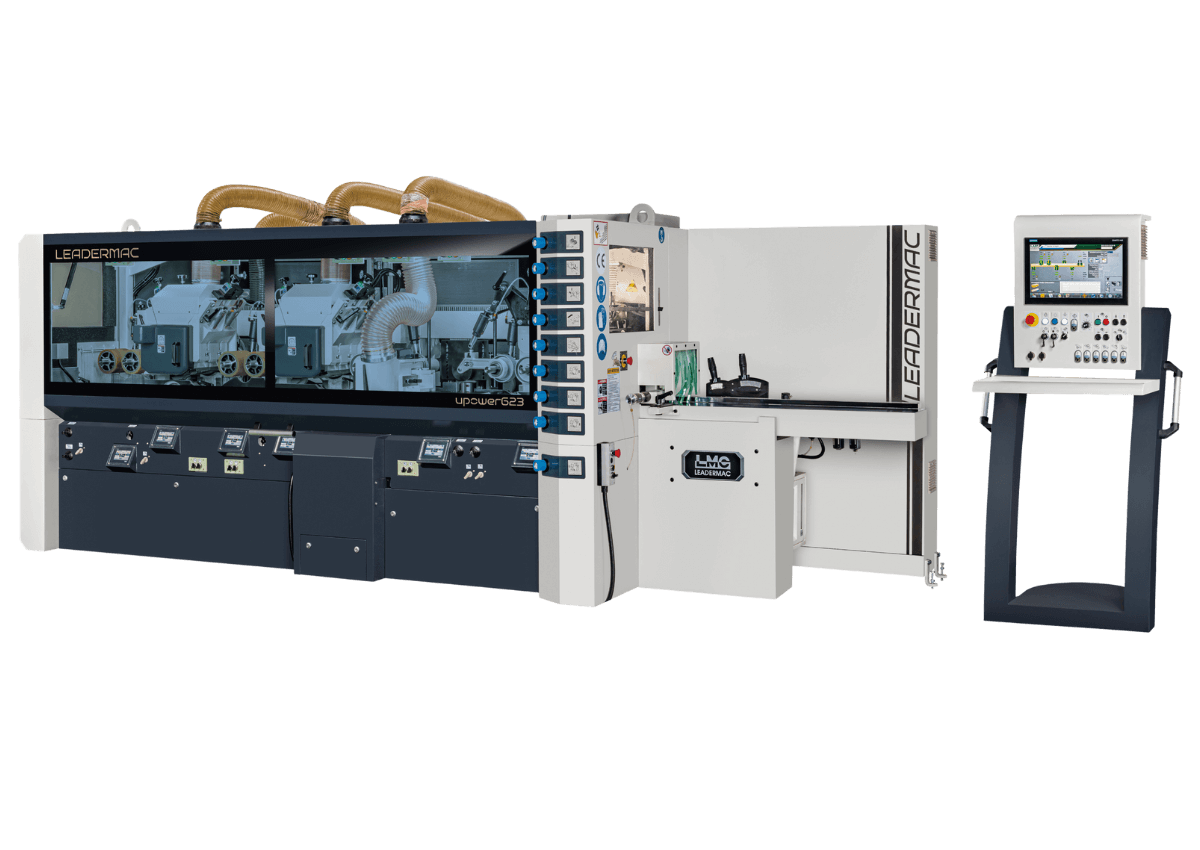

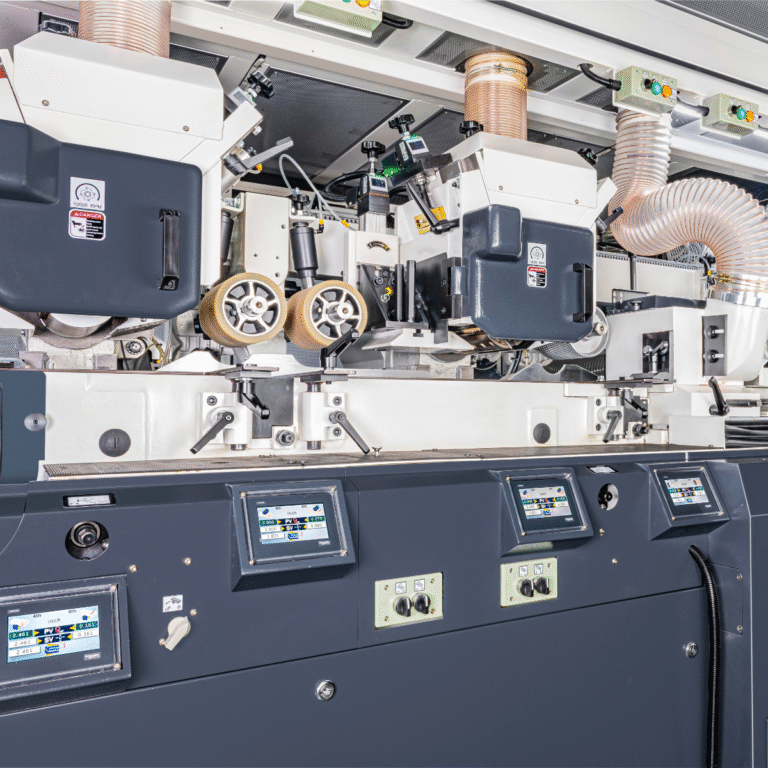

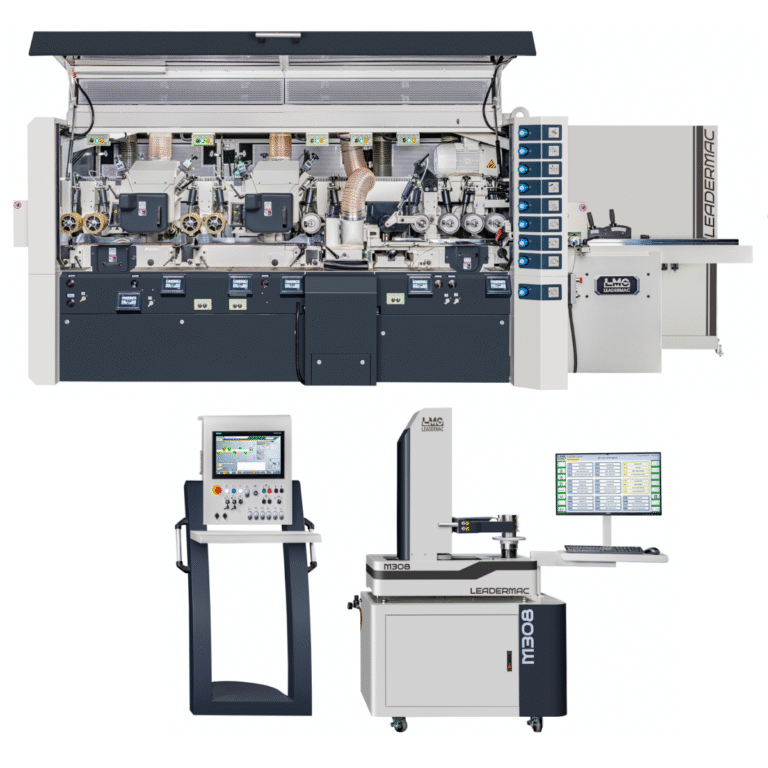

HSK uPower Planer Moulder

Leadermac’s new generation of power series is a highly efficient-side moulder and ideally suited to accurate moulding applications with high productivity.

Leadership Through Performance and Reliability

HSK uPower Planer Moulder

Leadermac’s new generation of power series is a highly efficient-side moulder and ideally suited to accurate moulding applications with high productivity.

Leadership Through Performance and Reliability

OUTSTANDING FEATURES

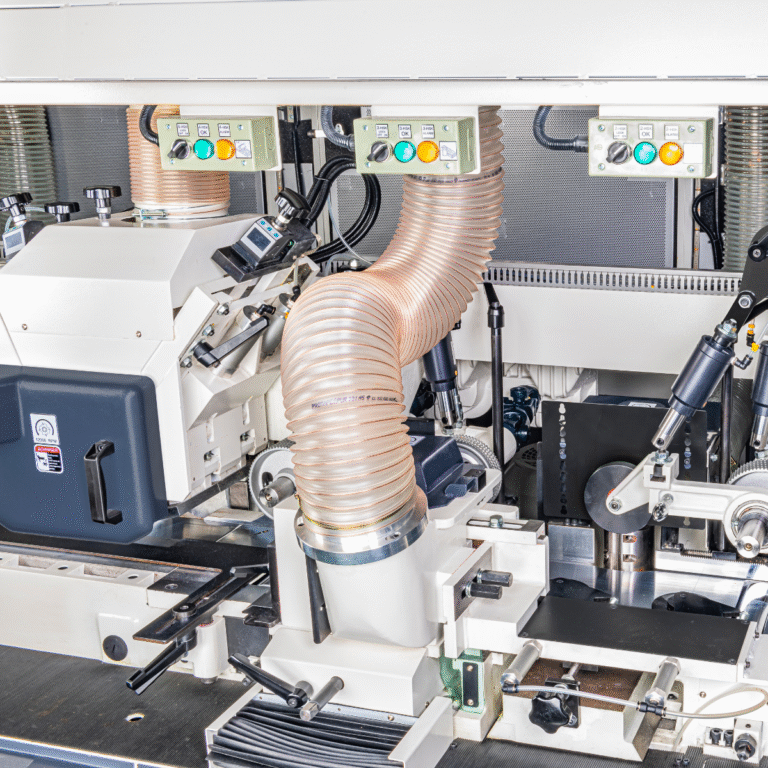

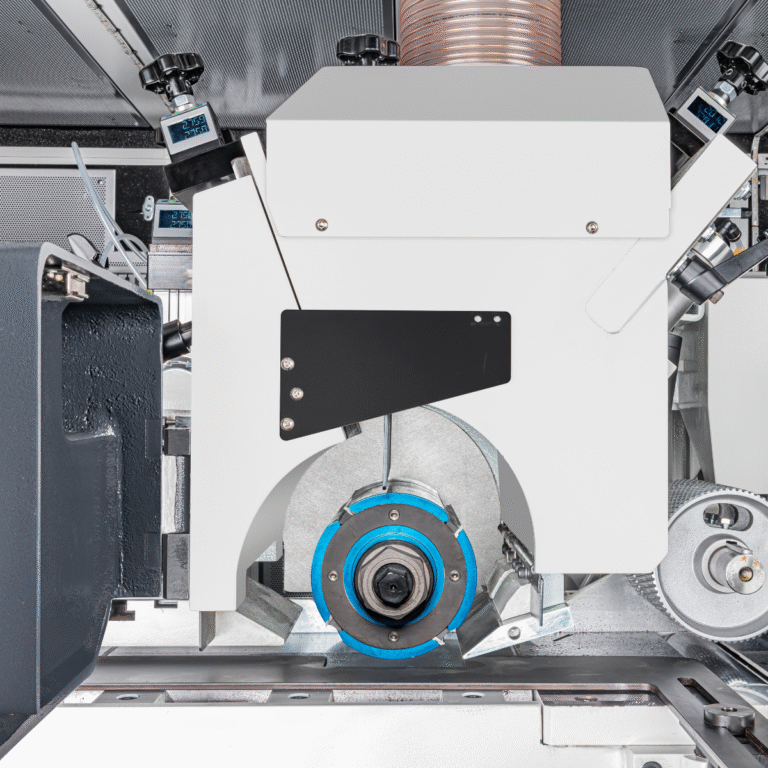

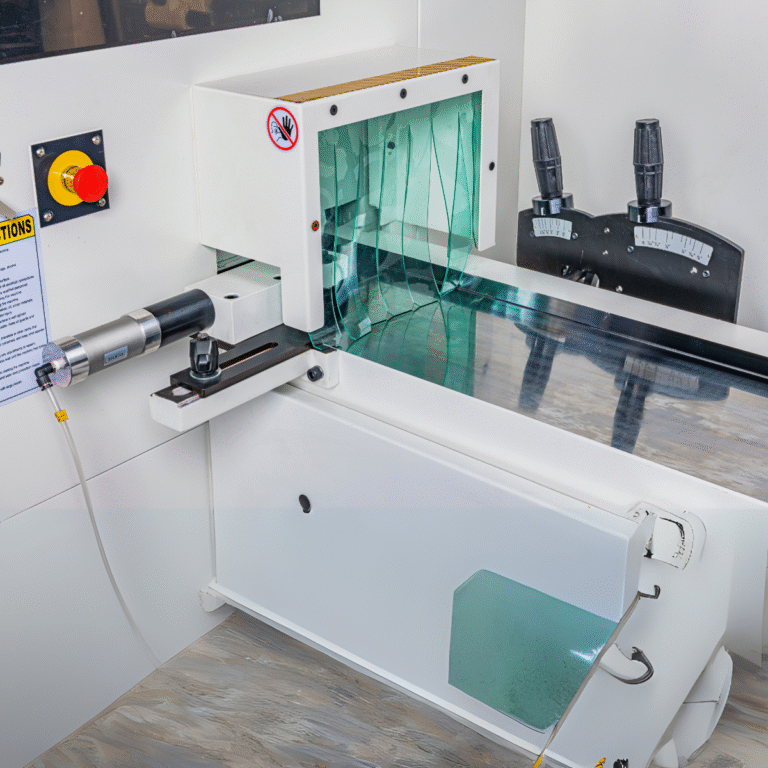

- 4,000-12000 RPM HSK Tooling on heads 2, 3, 4, 5, and 6 designed for optimal cut quality and precision, allowing for faster processing and reduced change over times.

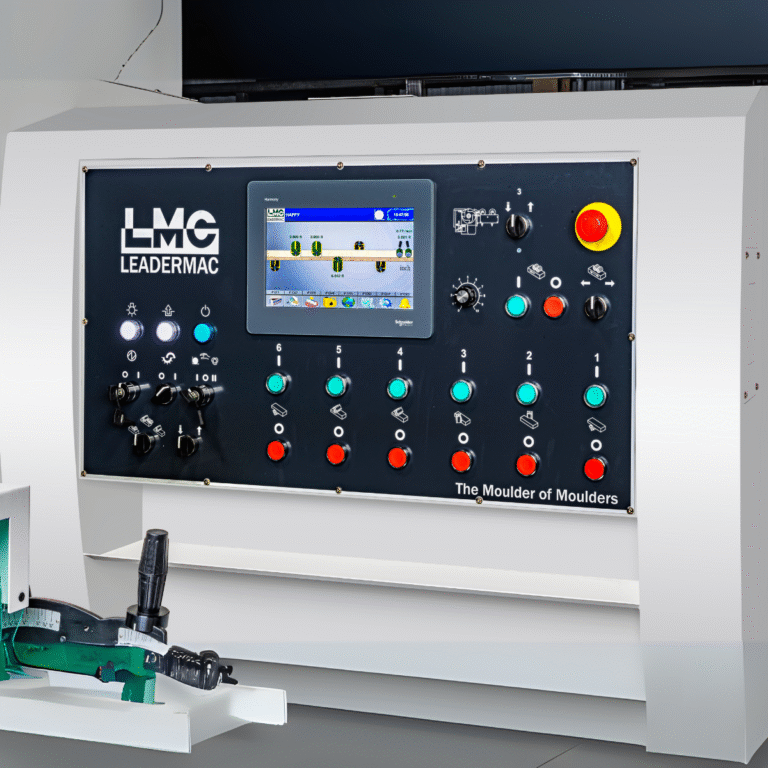

- Advanced ProSet software Integration: Provides intuitive control and streamlined operation, enabling quick setup, seamless changeovers, connectivity to the grinding room, and remote technician access. This system can recall 1,000 profiles and 10,000 individual tools.

- Ease of Use: User-friendly interface and design make operation straightforward, reducing the learning curve and operational complexity.

- Servo Placement Motors: Ensure precise and reliable adjustments, enhancing the accuracy of CNC-controlled spindle placement.

- Quick-Change Hardware: Including the RapidLock nut, telescoping feed wheel, and AP digital readouts on pressure components facilitates rapid changeovers and minimizes downtime, significantly boosting productivity.

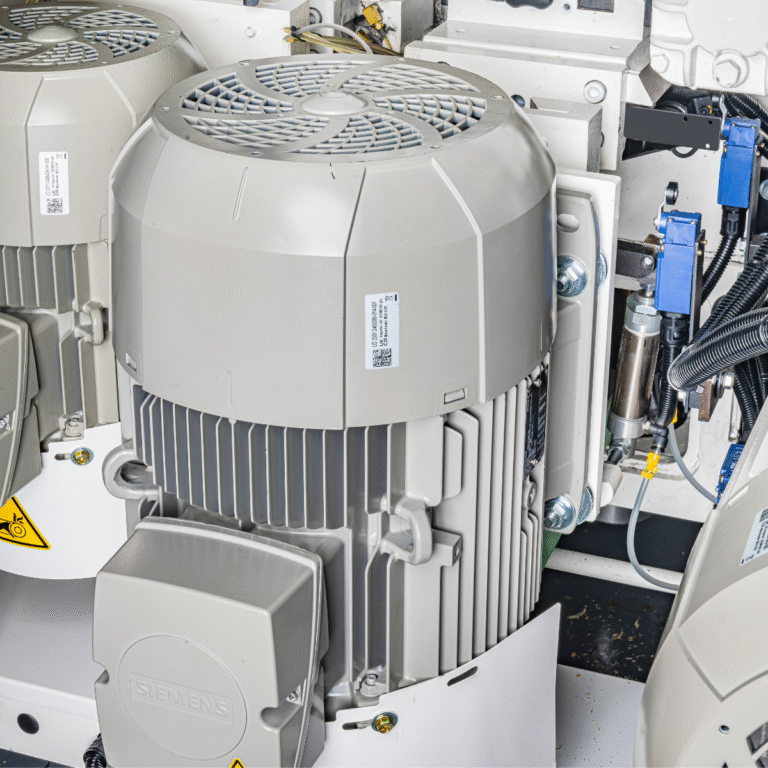

- The frame, designed for industrial excellence, our moulder features a robust cast iron frame that delivers unmatched weight, mass, and rigidity for vibration dampening. This superior construction ensures exceptional finished part quality.

- A tightly coupled Carden drive feed system ensures smooth and consistent feeding to assist in producing a high-quality finish.

FEATURES

TECHNICAL SPECIFICATIONS

| Thickness Material | ¼” to 6” |

| Width Material – You can actually run to 9 1/2″ (please discuss) | .6” to 9” |

| Axial adjust. side heads | 3.2” (80mm) |

| Axial adjust. top/btm heads | 1.6” (40mm) |

| Net weight | 15,800 lbs approximately |

| DESCRIPTION | HEAD HP | Spindle Type | RPM | CUTTERHEAD SWING | HOOD SIZE |

| 1st Bottom Head | 20 HP | 1 13/16” | 4,000- 8,000 | 4.9” to 7.1” (125–180 mm) | 5.9” (150 mm) |

| Right Side Head | 15 HP | HSK | 4,000-12,000 | 3.66” to 7.99” (93 – 203mm) | 5.9” (150 mm) |

| Left Side Head | 20 HP | HSK | 4,000-12,000 | 3.66” to 7.99” (93 – 203mm) | 5.9” (150 mm) |

| 1st Top Head | 25 HP | HSK | 4,000-12,000 | 3.66” to 7.99” (93 – 203mm) | 5.9” (150 mm) |

| 2nd Top Head | 25 HP | HSK | 4,000-12,000 | 3.66” to 7.99” (93 – 203mm) | 5.9” (150 mm) |

| 2nd Bottom Head | 25 HP | HSK | 4,000-12,000 | 3.66” to 7.99” (93 – 203mm) | 5.9” (150 mm) |

BESPOKE FACTORY OPTIONS

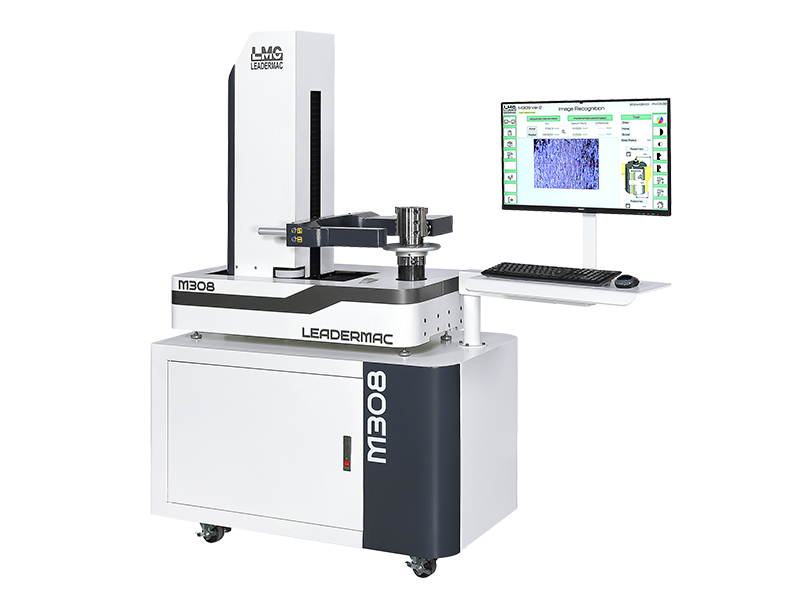

M308 Electronic Cutterhead Measurement Stand

The M308 offers the most accurate measurements of tools in the grinding room, connected to the moulder to update each tool’s measurements. M308 uses a video camera with an enhanced and enlarged image on a 27” monitor to give a clear, accurate view of the knife, its ground edge, etc. It comes with a heavy-duty base for mounting.

Why Leadermac uPower-HSK Moulder Series?

- Quick change HSK tooling system for rapid changeovers;

- ProSet software allows you to store profiles and setups for immediate recall;