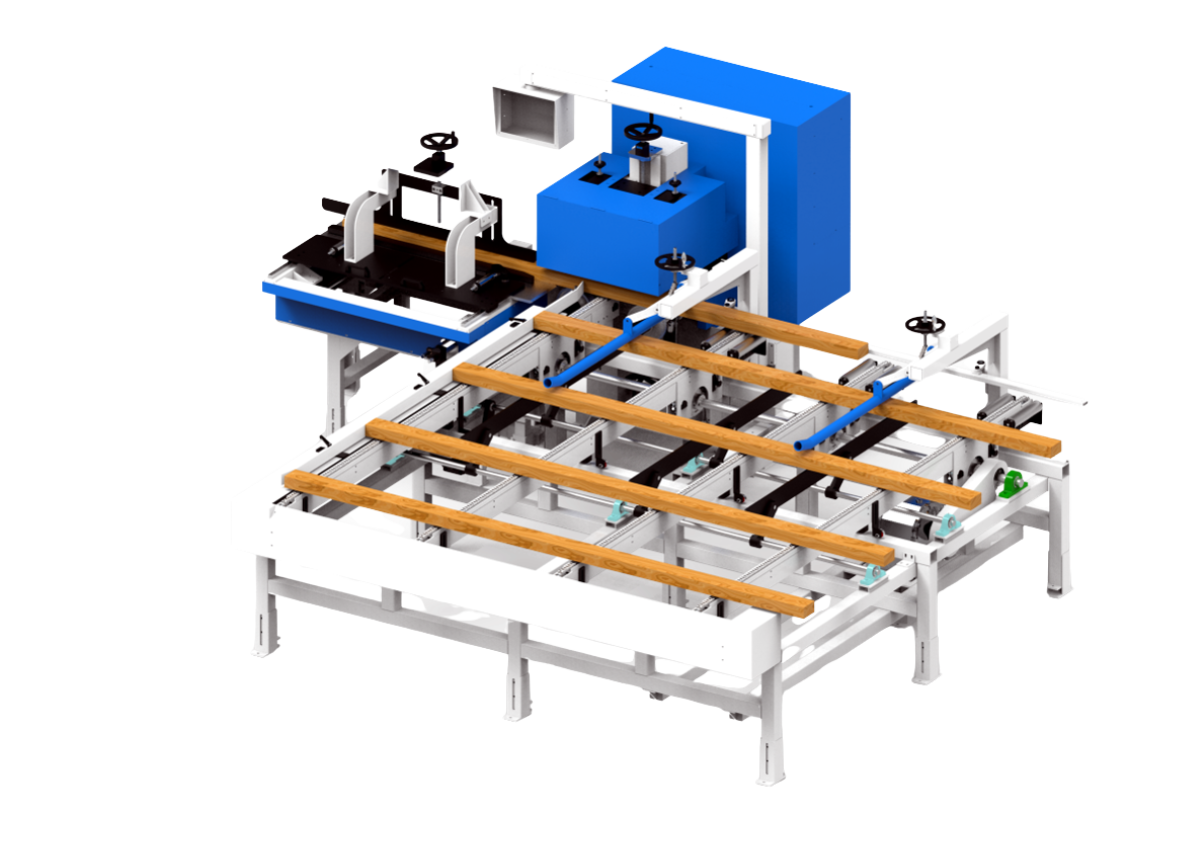

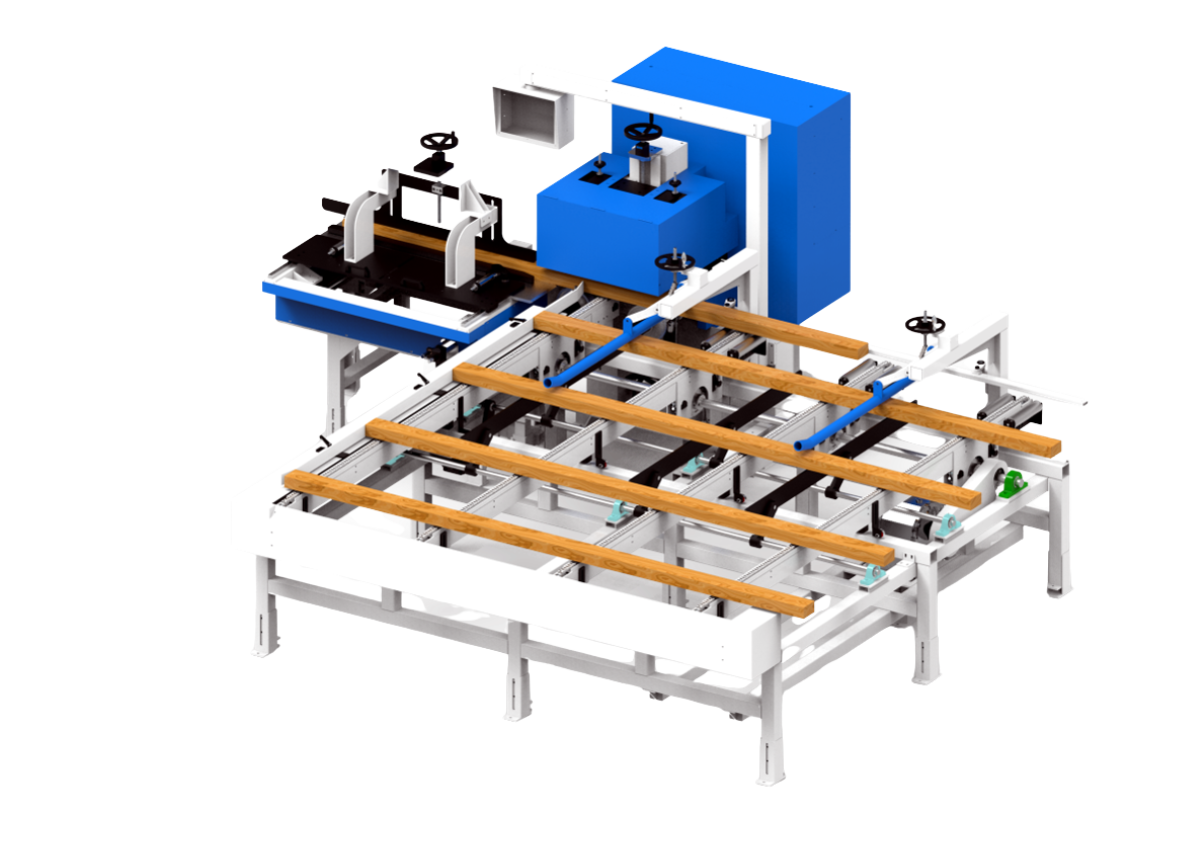

Lateral Infeed System

High-performance Automated Feeding system

Designed for precision, speed, and reliable operation, optimizing industrial automation and production efficiency.

Lateral Infeed System

High-performance Automated Feeding system

Designed for precision, speed, and reliable operation, optimizing industrial automation and production efficiency.

OUTSTANDING FEATURES

- This Lateral Infeed System ensures uniform feed delivery and good distribution.

- Modular trough / chain layout allowing the system to be configured to fit your floor plan (straight, 90° corners, legs or suspended)

- Durable chain and wear‑resistant components (e.g., large‑link chains, hardened corner wheels, lubrication‑free bearings) to reduce maintenance downtime and feed loss.

- Adjustable feed volume and/or chain speed to match different production/release schedules or feed types.

- Good accessibility for maintenance/cleaning (removable covers, easy corner access) and safe design for operator use.

- Reduced feed wastage by optimized trough design (rounded edges, minimal spillage, even feed flow) combining with chain speed and volume control.

FEATURES

TECHNICAL SPECIFICATIONS

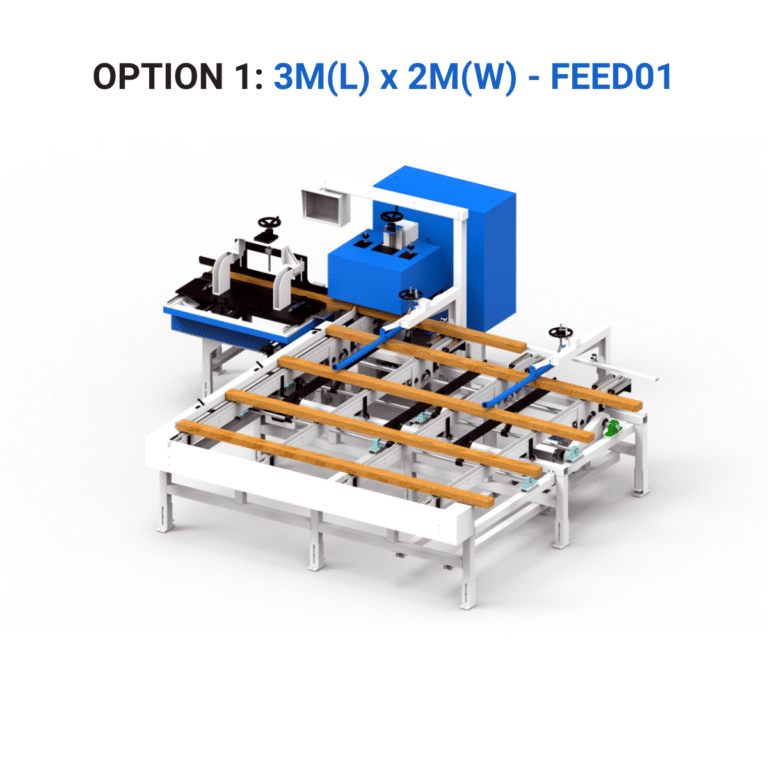

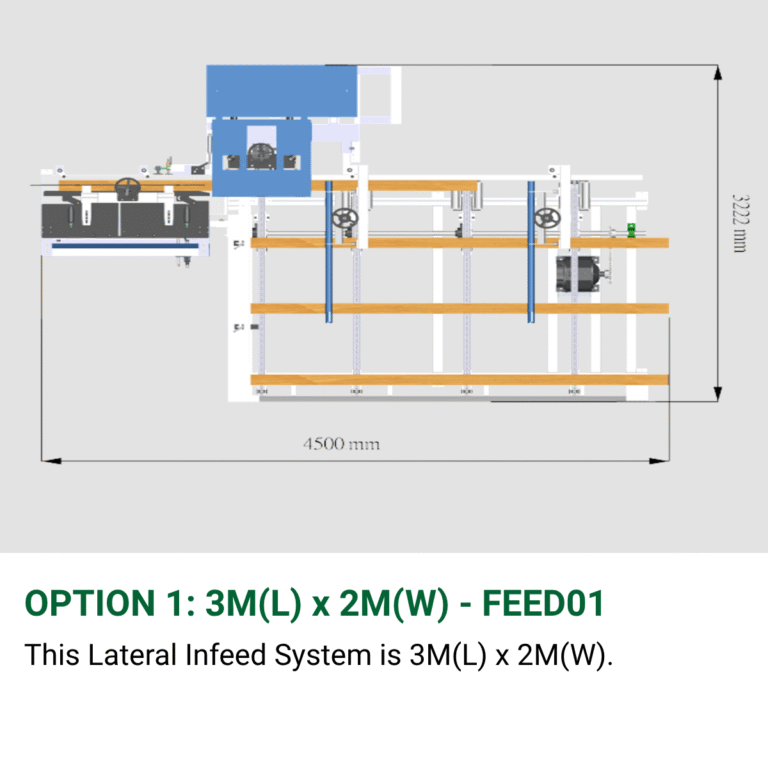

For a system sized ~3 m length × ~2 m width, below are typical numbers you might expect (these will need to be confirmed for the exact “FEED01” unit):

- Trough/chute length: ~3 m (as you specified) and width ~2 m for the feed bed area or footprint.

- Chain conveyor speed: perhaps a range e.g. 10‑40 m/min based on some chain feed systems.

- Drive motor power: e.g., around 0.37‑1.1 kW (for smaller poultry‑feed systems) depending on loading.

- Hopper/feed storage capacity: sizes vary (e.g., 140‑260 kg in some systems) with adjustable shutters.

- Material construction: galvanised steel trough, wear‑resistant chain links, possibly stainless components for aggressive/abrasive feed.

- System footprint/format: For horizontal systems, minimal incline; supports either on legs or suspended; corners available for routing.

- Circuit length: Some chain feeding systems support very long loops (100s of metres) but for a single line (3 m+2 m) your requirement is small so the system will be simpler.

- Control/automation: Manual or timer‑based control; optional variable speed/inverter feed drive.

- Standards / safety: Compliant with machinery directives, low‑voltage, CE etc. (depending on region)

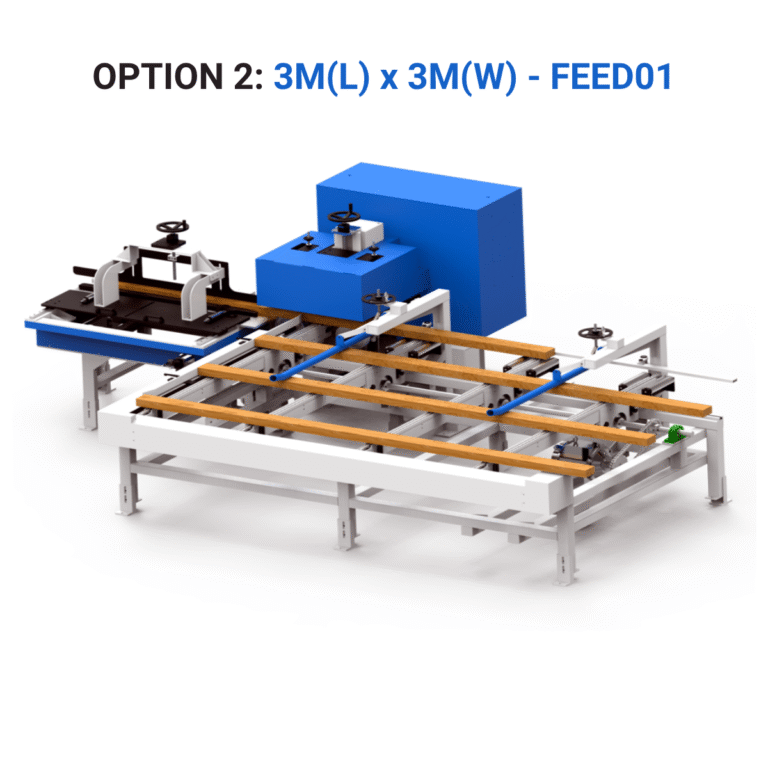

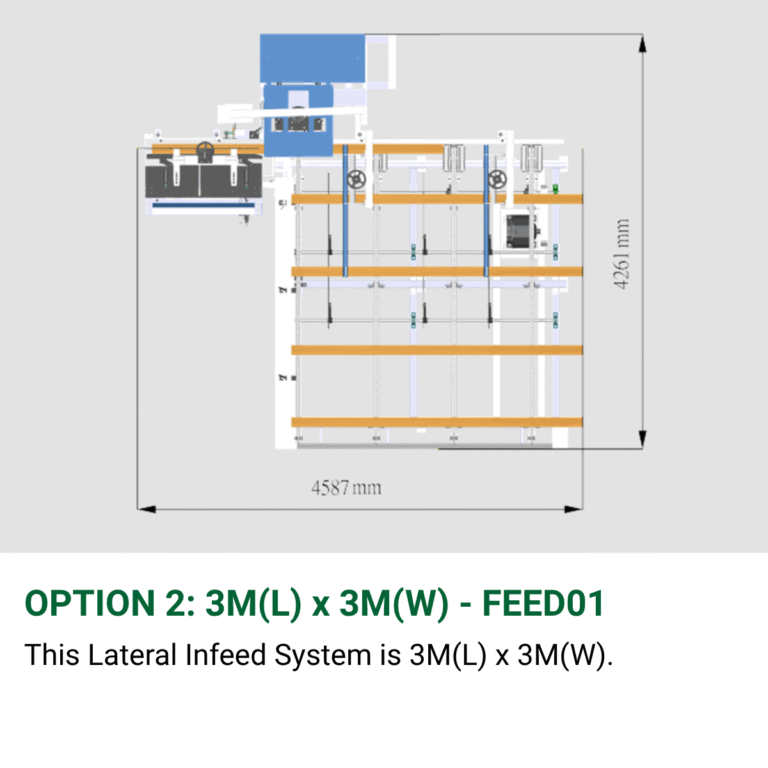

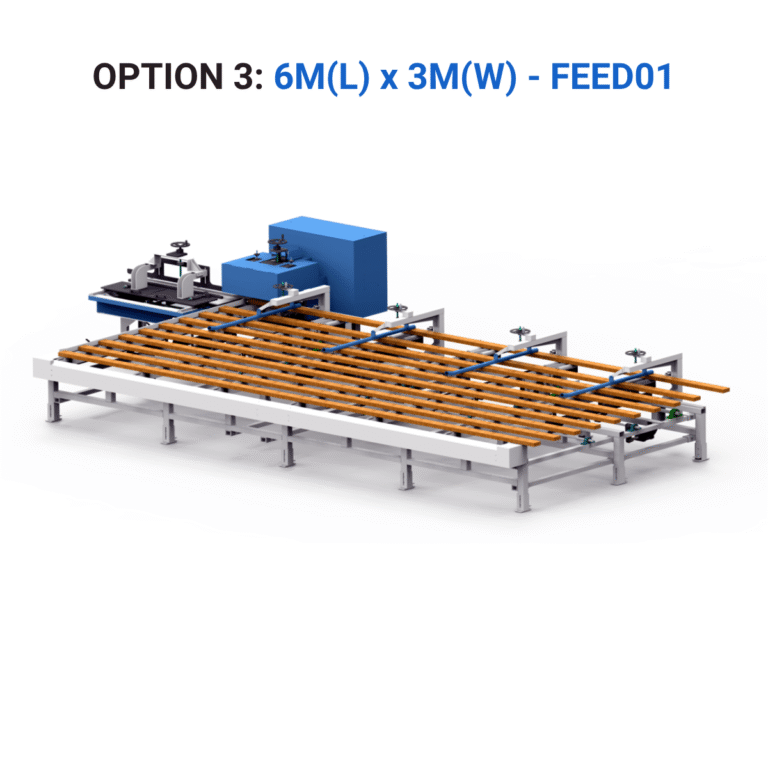

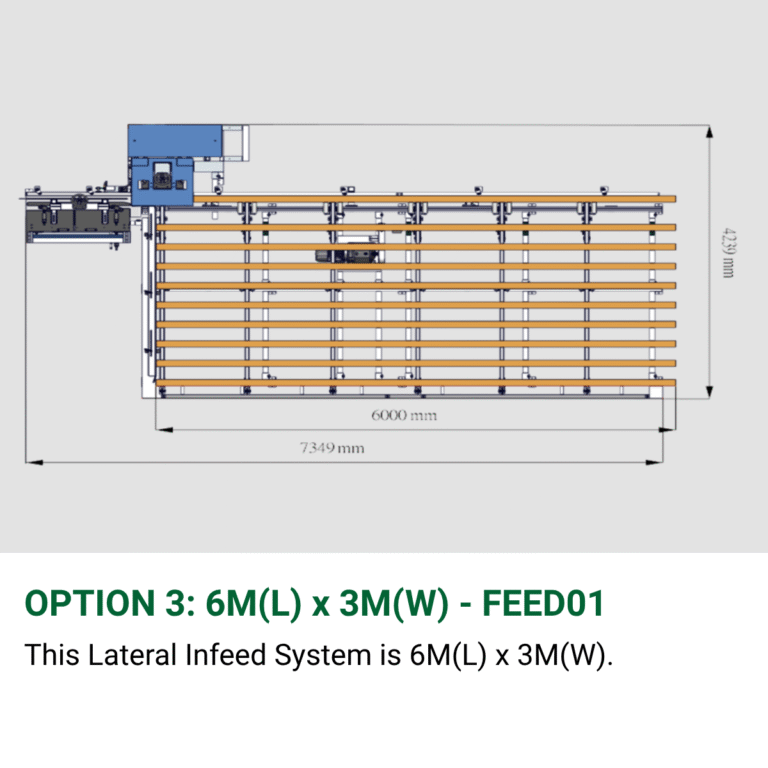

BESPOKE FACTORY OPTIONS

Custom-Built to Fit Your Space

Each system can be tailored to your requirements, with options such as:

-

Materials: stainless steel for corrosive or wash-down areas, or heavier-gauge steel for demanding applications

-

Chain & Drive: wear-resistant chains, special coatings, upgraded drives for higher speeds

-

Speed Control: variable-speed or inverter drives for adjustable feed rates

-

Layout: customised footprint, extra outlets, corners, or suspended/floor-mounted design

-

Hopper Options: larger capacity, multiple outlets, or direct-feed configurations

-

Automation: integration with sensors, PLCs or IoT systems for feed monitoring and control

-

Maintenance: quick-release joints, removable covers, easy-access supports

-

Surface Finish: galvanised, painted, anti-corrosion or food-grade coatings

-

Safety & Cleanliness: guards, dust extraction and spill-prevention features

-

Feed Type Adaptation: optimised for pellets, granules or powders through tailored chain speed and trough design